Summary: Ground Penetrating Radar (GPR) is a non-destructive utility locating method that uses high-frequency radio waves to detect buried utilities—both metallic and non-metallic—without digging. GPR improves safety by identifying underground hazards before excavation, helping contractors avoid dangerous utility strikes and meet OSHA and 811 requirements. It supports Subsurface Utility Engineering (SUE) standards like ASCE 38-22 by providing accurate, real-time imaging of subsurface features. By integrating GPR into pre-construction surveys, teams reduce excavation risks, prevent costly delays, and document compliance through visual radar data. GPR is especially effective in complex urban environments, delivering safe, precise utility detection across various soil conditions.

Before breaking ground on any construction or excavation project, accurately identifying subterranean utilities is a non-negotiable step in the process. Striking a buried cable, gas line, or water main doesn’t just stall a project—it introduces immediate safety hazards, triggers expensive repairs, and often leads to costly regulatory fines.

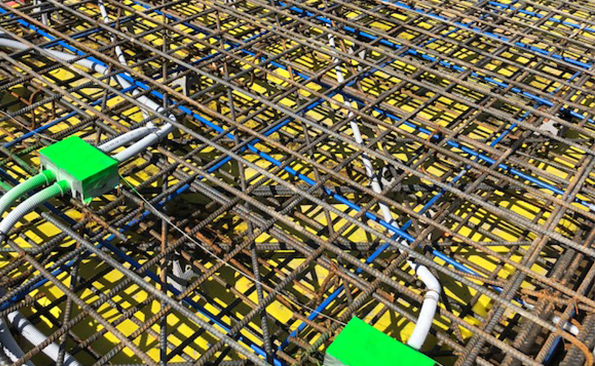

Today’s infrastructure is increasingly complex, with utility networks running deeper and denser than ever. Traditional detection methods can’t always keep pace. That’s where advanced technologies like Ground Penetrating Radar (GPR) play a strategic role, delivering precise subsurface imaging without disruption. As construction timelines tighten and safety expectations rise, GPR offers an essential edge in pre-construction planning.

Decoding Ground Penetrating Radar (GPR): A Look Inside the Technology

What Is GPR and How Does It Work?

Ground Penetrating Radar (GPR) is a geophysical method that transmits high-frequency radio waves into the ground to detect and map subsurface features. When the radar waves encounter materials with differing dielectric properties—such as soil, rock, water, or buried metal—they reflect back to the surface. These reflections are captured by a receiver and displayed as real-time data on a visual interface.

The entire process hinges on electromagnetic wave propagation. GPR systems operate typically in the frequency range of 10 MHz to 2.6 GHz. Lower frequencies penetrate deeper but deliver lower resolution; higher frequencies provide sharper images but shallower depth. Operators select frequency levels based on the required depth of investigation and the resolution needed.

Key Components of GPR Systems

Every GPR system relies on three integrated components to function effectively:

-

Antenna: This element transmits the radar pulses into the ground and receives the returning signals. Antennas are often shielded to reduce interference and noise.

-

User Interface: This includes the display screen and control units, allowing technicians to visualize data in real time, adjust settings, and store scans for post-processing.

-

Processing Unit: The onboard computer interprets raw signal returns, converting electromagnetic reflections into radargrams—graphical representations of subsurface features. Advanced processing software allows for filtering, depth calibration, and visualization in 2D and 3D formats.

Some modern GPR units come integrated with positioning systems, battery packs for field mobility, and rugged casings suitable for construction environments. These configurations streamline on-site operations and support extended surveys with minimal setup time.

How GPR Differs from Traditional Utility Detection Methods

Unlike electromagnetic locators that require tracer wires or contact with metallic lines, GPR detects both metallic and non-metallic utilities, including plastic pipes, concrete conduits, and voids. While traditional methods like inductive and conductive locating only trace active lines, GPR offers comprehensive detection through material contrast rather than signal transmission.

GPR also surpasses visual inspection and potholing, which are invasive by nature. Instead of disrupting the ground, GPR scans directly from the surface, delivering immediate results without the need for excavation. This non-intrusive capability makes GPR invaluable in urban environments, heritage sites, and facilities with dense utility networks.

The ability to create subsurface maps with precise spatial context grants GPR a distinct edge in modern utility locating, especially when combined with geospatial tools or CAD-based project planning platforms.

Unlocking the Advantages: How GPR Enhances Utility Detection and Mapping

Accurate Detection of Buried Utilities

Ground Penetrating Radar (GPR) systems provide high-resolution subsurface imaging that helps pinpoint the location of hidden utilities before excavation begins. With frequencies ranging from 100 MHz to over 2000 MHz, GPR can balance penetration depth and resolution to match project requirements. Operators can detect pipes and cables with precision in both horizontal and vertical dimensions, reducing guesswork and unnecessary exploratory digging.

Performance Across Diverse Soil and Site Conditions

Unlike some other detection methods, GPR adapts well to a variety of soil compositions. It performs reliably in dry sandy soils, clay-heavy ground, and even compacted urban subgrades. While highly conductive materials like wet clay can reduce signal clarity, advancements in antenna design and signal processing software have minimized this limitation. Whether the project site includes pavement, reinforced concrete, or landscaped soil, GPR continues to deliver usable results.

Identification of All Utility Types—Metallic or Not

GPR does not rely on the conductive properties of materials to establish a target location. Where electromagnetic locators require metallic content for detection, GPR can successfully identify both metallic (steel, copper, aluminum) and non-metallic (PVC, HDPE, fiberglass) utility lines. This capability makes it indispensable for comprehensive utility mapping on legacy sites where pipe material records may be incomplete or inaccurate.

Real-Time Feedback for On-Site Decision Making

Modern GPR systems offer real-time data visualization through integrated display units or tablets. Field technicians can interpret subsurface signals instantly, mark detected utilities directly on the ground surface, and adjust scanning paths dynamically. This immediate feedback loop streamlines the survey process, enables rapid adjustment to unexpected findings, and significantly reduces return trips or site delays.

-

Faster readiness: No need to wait for post-survey processing.

-

Greater accuracy: Immediate adjustments improve coverage quality.

-

Improved communication: On-site teams can align decisions with what the radar shows in real time.

Consider a congested urban site: multiple utilities may overlap within the same trench. With GPR, survey crews eliminate guesswork by viewing stratified layers and anomalies on the spot. That degree of information depth transforms how teams plan the next steps—no time wasted, no surprises underground.

Boosting Subsurface Utility Engineering (SUE) Accuracy with GPR

Linking GPR and SUE: A Precision-Oriented Partnership

Subsurface Utility Engineering (SUE) plays a foundational role in uncovering, assessing, and documenting underground utility data during project planning and construction. The integration of Ground Penetrating Radar (GPR) directly supports the American Society of Civil Engineers (ASCE) 38-22 SUE standard — a benchmark for defining utility data quality. Within this standard, GPR enhances both Level B (mapped via surface geophysics) and Level A (verified through direct exposure) data classifications.

The Role of GPR in Achieving Higher ASCE 38-22 Quality Levels

GPR contributes to higher data accuracy by generating real-time imaging of subsurface conditions without excavation. When used during the geophysical survey phase (Quality Level B), GPR creates horizontal positioning data for utilities using electromagnetic wave reflection principles. This information guides targeted test hole excavation during Level A assessments.

-

In Quality Level B surveys: GPR identifies non-metallic and metallic pipes, detecting conduits that may be missed by traditional electromagnetic locating tools.

-

For Quality Level A verification: GPR output directs vacuum excavation precisely over target anomalies, minimizing disruption and maximizing exposure accuracy.

Utilities buried in complex subsurface environments—such as concrete-embedded electric lines or non-metallic water mains—benefit significantly from GPR’s depth penetration and spatial resolution. The result: engineering teams make more informed decisions, and unexpected on-site discrepancies decline.

Field-Proven Results: Reduced Risk, Time and Rework

Several infrastructure and transportation projects across North America illustrate GPR’s concrete impact on SUE implementation. On a highway expansion project in Ontario, pairing GPR with electromagnetic detection trimmed utility investigation effort by 30%, while reducing utility conflicts after design submission by 45% according to data shared by GeoScan Subsurface Surveys. In another case, a major hospital redevelopment project in Seattle used GPR-augmented SUE to reduce potholing requirements by two-thirds, with zero utility strikes reported during initial excavation.

These results underscore GPR’s value in transforming SUE from a risk-mitigation exercise into a proactive strategy. Integrating radar data with SUE workflows refines digital utility maps, provides clearer design basis reports, and minimizes change orders during construction.

Is your infrastructure project leveraging GPR to its fullest potential within SUE protocols?

Increasing On-Site Protection: How GPR Supports Construction Safety

Preventing Utility Strikes That Threaten Lives

Underground utility strikes can trigger deadly accidents. According to the Common Ground Alliance’s 2022 DIRT Report, over 213,000 damage incidents were reported in North America, many involving water, gas, electric, and telecommunications lines. Misjudging the exact location of these utilities results in explosions, electrocution, and long-term service disruptions.

Ground Penetrating Radar (GPR) plays a direct role in eliminating guesswork. By identifying the depth, position, and orientation of concealed utilities, it enables immediate on-site decisions that prevent accidental hits. The non-invasive nature of GPR allows operators to detect both metallic and non-metallic lines, improving accuracy where other systems rely on conductivity.

Mitigating Risks During Trenching, Boring, and Excavation

Trenching is responsible for some of the most dangerous tasks on a construction site. A miscalculated dig can rupture a gas line in seconds. Traditional locating methods often miss targets or produce ambiguous signals, especially in areas with multiple overlapping infrastructures.

GPR equips field teams with real-time subsurface imaging before heavy equipment breaks ground. Whether the task involves horizontal directional drilling (HDD), microtunneling, or vacuum excavation, operators can mark locations with higher confidence. This reduces mechanical conflicts and stops projects from turning into emergency response scenes.

Creating a Safer Work Environment for Everyone on Site

Safety managers and site supervisors embed GPR surveys into routine pre-construction planning because the data directly protects workers. It produces clear visualizations that are easy to interpret and share across teams, which improves coordination in high-risk zones.

-

Contractors use GPR data to avoid contact with pressurized lines.

-

Engineers verify design plans against actual utility positioning.

-

Operators rely on scan results to adjust machinery movement paths.

Every scan reduces uncertainty. Fewer surprises behind the surface mean lower exposure to confined space hazards, electrical risks, and rapid response emergencies. GPR doesn’t just uncover what’s below — it reshapes how crews move safely above it.

Accelerating Excavation Projects While Cutting Costs

Faster Utility Location Than Traditional Methods

Ground Penetrating Radar (GPR) significantly reduces the time needed to identify buried utilities. Traditional techniques, such as visual inspection of archived site plans or hydro-vacuum excavation, can take hours or even days, particularly in urban areas with dense infrastructure. GPR, by contrast, can scan a worksite in real time, often detecting pipes, conduits, and cables within minutes. Complex sites that once required prolonged surveying now benefit from rapid subsurface assessment without interrupting surface operations.

For example, a standard GPR survey crew can scan up to 1,000 to 2,000 square feet per hour, depending on site conditions and utility density. This outpaces the average output of manual locating crews, especially in scenarios requiring permits or disruptive digging to confirm utility presence.

Minimizing Project Delays from Undetected Utilities

Undetected or misidentified subsurface utilities are among the leading causes of project delays. According to the Common Ground Alliance’s 2022 DIRT Report, there were 213,792 reported utility damages in the U.S. alone, many of which resulted in unplanned work stoppages and budget overruns. Each incident not only adds days to project timelines but can also increase costs by tens of thousands of dollars.

By generating high-resolution images of underground features, GPR enables teams to map risk zones and avoid hitting buried assets. This foresight reduces the need for last-minute design changes or emergency repairs, keeping excavation timelines on track. Where other methods may leave blind spots, GPR adds clarity, lowering the probability of schedule disruptions due to unseen infrastructure.

Streamlining Excavation with Precise Pre-Dig Plans

Excavation that begins with accurate utility location data minimizes material handling, labor costs, and rework. GPR delivers detailed location and depth measurements, which feed directly into pre-dig planning. Project managers can designate safe dig zones, optimize equipment routes, and assign resources more effectively.

-

Contractors avoid unnecessary trenching, reducing equipment wear and fuel consumption.

-

Excavators work with confidence, eliminating guesswork and minimizing exposure to liability.

-

Mapping data integrates into CAD or GIS platforms, aligning with digital workflows and enhancing project documentation.

Pinpointing underground utilities before the first shovel hits the soil transforms excavation from a reactive to a proactive process. This shift doesn’t just improve safety—it delivers tangible savings across labor, timelines, and budget allocations.

Non-Destructive Testing (NDT): Inspecting Without Damaging

Examining What’s Beneath Without Cutting Into It

Non-Destructive Testing (NDT) through Ground Penetrating Radar offers a precise method to inspect subsurface conditions while leaving the surface untouched. Instead of breaking ground or drilling exploratory holes, GPR transmits high-frequency radio waves into the ground and maps the reflections of these waves to identify buried utilities. This method eliminates the need for direct access to the utility conduit during initial assessments.

Why Avoid Invasive Techniques Like Potholing?

Potholing, also known as daylighting, involves excavating a physical hole to verify the location of underground utilities. Although accurate, it brings a set of drawbacks—site disruption, high labor costs, and potential for accidental damage. GPR bypasses these risks entirely. The technology captures data in real time, mapping utilities at various depths, and requires no contact with the utility line. When comparing the two:

-

Potholing: Requires heavy equipment, disrupts traffic flow, and affects site schedules.

-

GPR-based NDT: Operates with minimal surface contact, allowing for faster asset detection and decision-making without soil disturbance.

Preserving Site Integrity While Unveiling Critical Data

Every construction site has existing surface structures, vegetation, or sensitive ground layers. Excavation, even on a small scale, can compromise these elements. GPR gathers detailed structural and locational utility data without impacting the physical environment. In dense urban settings, historical areas, or ecologically sensitive zones, this advantage becomes pivotal. GPR scans preserve pavement, sidewalks, and landscaping while still producing utility maps with positional accuracy commonly within +/- 10 centimeters, depending on soil conditions and equipment frequency.

When considering how to keep a site both productive and intact, GPR emerges not as a luxury, but as the practical approach. Non-destructive testing using GPR ensures that teams get answers without leaving scars on the surface.

Meeting Compliance: How GPR Aligns with Regulatory Standards and Guidelines

Understanding the Regulatory Environment for Utility Location

Across the United States, utility detection on construction sites operates under a framework of federal, state, and municipal regulations. The most referenced national standard, ASCE 38-22, published by the American Society of Civil Engineers, defines the Quality Levels (A through D) used in Subsurface Utility Engineering (SUE). States often adopt and expand upon this framework to ensure consistent, accurate mapping and risk reduction strategies in excavation zones.

In addition, every state enforces its own version of 811 “Call Before You Dig” laws, which mandate that utilities be located and marked before any excavation begins. Regulations also emphasize strict adherence to utility damage prevention programs and enforce penalties for non-compliance.

How GPR Contributes to OSHA and 811 Compliance

The Occupational Safety and Health Administration (OSHA) regulation 29 CFR 1926.651(b) requires employers to determine the estimated location of utility installations—such as sewer, telephone, fuel, electric, water lines—prior to excavation. Ground Penetrating Radar fulfills this requirement by enabling high-resolution scans that identify subsurface materials without intrusive digging techniques.

GPR complements utility locator flags and markings resulting from a standard 811 inquiry by adding precision and clarity. Especially in congested urban zones or in historically undocumented areas, GPR helps fill in gaps that conventional utility maps or electromagnetic locators may miss. When used in tandem with ASCE 38-22-compliant practices, GPR enables projects to move forward with documentation that withstands regulatory audits.

Documenting Findings for Legal and Operational Compliance

GPR scans produce visual data—radargrams—that, when interpreted by certified technicians, can be stored, tagged, and integrated into digital records. These records then form part of the official utility mapping required for permitting processes and inspections. Construction contractors can present this documentation to demonstrate adherence to local ordinances, engineering protocols, and insurance requirements.

-

Federal compliance: Satisfies OSHA’s excavation safety requirements through pre-dig utility location.

-

State-level mandates: Supports state-specific rule enforcement under 811 laws by providing additional utility traceability.

-

Municipal guidelines: Enables accuracy in reporting utility positions during permit applications and inspections.

Inspection teams and project managers rely on the clarity of GPR-generated utility reports to demonstrate legal due diligence. These same reports also support post-construction assessments and future project planning documents.

Proactive Damage Prevention and Risk Mitigation Through Accurate Utility Detection

Accidental strikes on underground utilities cause more than just physical damage. They trigger cascading effects—costly delays, outages that impact entire communities, and lawsuits that stretch legal teams and insurance coverage. Accurate detection with ground penetrating radar (GPR) stops these chain reactions before they start.

Avoiding Outages, Lawsuits, and Repair Costs

Each year, utility strikes cost industries billions. According to the Common Ground Alliance’s 2021 Damage Information Reporting Tool (DIRT), there were over 192,000 reported damages to underground utilities in the United States alone. The estimated societal cost of these accidents exceeds $30 billion annually, including direct repair costs, project delays, and legal disputes.

When used during pre-construction utility surveys, GPR reliably pinpoints non-metallic and metallic utilities—even in complex urban environments. Unlike traditional electromagnetic detection, GPR can locate PVC, concrete, clay, and other materials invisible to conductive methods. This level of precision minimizes the risk of cutting power, water, gas, or fiber optic lines during excavation.

Establishing Long-Term Utility Records

Accurate data collected with GPR does more than mitigate immediate risk. It builds a foundation for the future. Once captured, subsurface utility maps can be digitized and archived as part of a project’s as-built documentation. These records enable project teams, facility owners, and future contractors to avoid rediscovery costs, verify utility paths during renovations, and streamline permitting processes.

In cities where undocumented or inaccurately mapped utilities are common, detailed GPR surveys drastically reduce redundancy and project inefficiencies. Utility infrastructure from decades past—once entirely unknown—can now be precisely located and recorded for next-generation planning.

Reducing Liability in the Eyes of Insurers

Insurance underwriters factor risk assessment rigor into coverage terms. When engineering teams demonstrate use of proven detection methods like GPR, insurers are more likely to offer favorable premiums and comprehensive coverage terms. Courts and regulatory bodies increasingly use this level of due diligence as a benchmark to determine negligence in utility strike cases.

-

GPR usage shows adherence to industry best practices and reduces the chance of being found professionally liable following a subsurface incident.

-

Documented GPR surveys serve as admissible evidence during legal and insurance claims, proving that a project team took appropriate steps to locate and avoid buried utilities.

-

Fewer incidents mean fewer claims—helping maintain low Experience Modification Rates (EMRs), a key metric in securing future project bids.

By integrating GPR into the detection phase, project teams create a protective barrier against errors that would otherwise result in disruption. Not by chance, but by precise, data-driven detection.

Smarter Data Management: Integrating GPR with GPS and GIS

Precision Geotagging with GPS

Pairing Ground Penetrating Radar (GPR) with Global Positioning System (GPS) equipment enables precision in mapping subsurface utilities. During a survey, as GPR scans beneath the surface, GPS devices capture the exact coordinates of each scan lane. High-accuracy GPS solutions—typically Real-Time Kinematic (RTK) or Post-Processed Kinematic (PPK)—can provide location data accurate to within a few centimeters.

This level of spatial precision means buried pipes, cables, or voids aren’t just detected—they’re located exactly where they are. Contractors can then overlay this data onto site plans or CAD files with confidence, minimizing guesswork and reducing the risk of utility strikes.

Seamless GIS Integration for Asset Documentation

Once field teams collect GPR and GPS data, the information moves into Geographic Information Systems (GIS). In a GIS platform, utility locations are visualized alongside other spatial datasets such as property boundaries, pavement layers, or zoning maps. GPR outputs—often amplitude slices, hyperbola patterns, and depth profiles—can be formatted as georeferenced raster layers and layered over base maps.

This integration creates a centralized geospatial asset inventory, facilitating long-term infrastructure planning and utility lifecycle tracking. Municipalities, service providers, and large infrastructure managers use this data to update their digital twins and maintain accurate as-builts.

Boosting Project Coordination Through Digital Visualization

Translating ground-truth GPR data into digital formats sharpens communication between engineers, planners, and on-site crews. Interactive 2D and 3D visualizations—generated using GIS or BIM software—offer a detailed view of hidden utilities mapped to scale. This allows teams to coordinate trenchless technology paths, staging zones, and excavation boundaries in advance.

-

Utility conflicts show up clearly during design reviews, long before digging starts.

-

Change orders tied to unknown obstructions drop significantly.

-

Stakeholders gain access via cloud-based dashboards, streamlining approvals and updates.

With GPS logging GPR paths and GIS contextualizing their significance, the data becomes actionable intelligence. Coordination improves. Downtime shrinks. Every scan turns into a long-term asset.

Maximizing Infrastructure Longevity with GPR Utility Mapping

Precision Schematics Streamline Maintenance and Repairs

Accurate underground utility schematics obtained through Ground Penetrating Radar (GPR) provide maintenance teams with a reliable reference for locating pipelines, cables, and conduits. This eliminates the guesswork traditionally involved in subsurface work and allows for direct access to known assets. As a result, field crews can target problem areas more efficiently, avoiding unnecessary trenching and minimizing service disruptions.

For public utilities, telecom companies, and municipal services, GPR-derived subsurface maps reduce dependency on outdated or incomplete paper records. This clarity accelerates both routine servicing and urgent repairs. For instance, detecting the exact location and depth of aging water mains or fiber-optic lines prevents accidental damage during maintenance—shortening repair timelines and preserving system uptime.

Enabling Predictive Maintenance Through Asset Condition Insights

When integrated into recurring inspection cycles, GPR enables a proactive approach to asset care. By capturing data on subsurface anomalies, corrosion patterns, and material degradation, operators can identify components approaching failure before visible symptoms occur. This predictive capability shifts operations from reactive fixes to scheduled interventions that extend the service life of the infrastructure.

In sectors like gas distribution or electrical transmission, this insight profoundly reduces the risk of large-scale outages or hazardous failures. Recurrent GPR scans build a temporal dataset, allowing analysts to model wear trends and anticipate which underground assets will require replacement or reinforcement in upcoming fiscal years.

Legacy Data Fuels Smarter Infrastructure Upgrades

Urban development often relies on historical utility layouts to plan new installations. GPR fills in the gaps where original as-built drawings are missing or where undocumented modifications have been made. By compiling legacy data through digital mapping platforms, planners can overlay subsurface realities with future expansion models. This ensures designs account for existing constraints upfront—whether that’s rerouting a stormwater basin or upgrading power infrastructure without disturbing telecom backbones.

In cities managing 19th or early 20th-century infrastructure, knowing precise positions of cast iron water mains or ceramic sewer pipes provides engineers with a foundation upon which modern infrastructure can be layered. Reusing validated spatial data from GPR also reduces duplication of surveys, cutting overall project lead times and costs for long-term urban renewal initiatives.

Choosing the Right GPR Equipment and Service Provider

Identifying High-Quality GPR Equipment

The effectiveness of a ground penetrating radar system relies heavily on the quality of its components. GPR units with a wide frequency range deliver better resolution and depth penetration versatility. For utility detection, systems operating within 250 MHz to 1000 MHz strike the right balance — lower frequencies penetrate deeper, while higher frequencies provide finer detail for shallow targets.

Look for hardware with real-time data processing, high dynamic range, and robust filtering algorithms. These features improve clarity in complex subsurface environments. Equipment designed with rugged, weather-resistant housing ensures reliable field performance under all conditions. Battery life, ease of calibration, and data export options also make a tangible impact on overall productivity.

Mobile Systems or Handheld Units?

Choosing between mobile and handheld GPR systems depends on project scope and site conditions. Mobile platforms — often vehicle-mounted or cart-based — are ideal for covering large areas quickly. They’re commonly deployed on roadways, airports, and expansive construction sites, where speed and efficiency are critical.

Handheld units, on the other hand, offer the flexibility needed for restricted areas, vertical surfaces, and localized investigations. Their lightweight construction and maneuverability allow for detailed scanning in trenches, narrow alleyways, or around existing structures. Hybrid systems, which allow switching between modes, add another layer of adaptability.

Partnering with Specialized Service Providers

Working with a GPR service provider who understands both the technology and the construction environment prevents costly misinterpretations. Top-tier providers bring certified technicians, advanced data interpretation skills, and field experience across diverse subsurface conditions. They don’t just operate equipment — they contextualize the findings for engineering and safety teams.

When evaluating partners, ask direct questions: Do their technicians hold certifications such as NULCA/USC trained locator credentials? Can they demonstrate experience on utility-heavy urban sites? What post-project deliverables do they provide — just a raw scan or full georeferenced mapping?

Incorporating GPR into a project workflow begins with the right tools and the right people. Choose a solution that matches subsurface complexity with data clarity. Then select a service provider who translates that data into actionable insight.

Building Safer, Smarter Projects With GPR

Every construction project demands precision and accountability—hidden utilities shouldn’t be left to guesswork. Ground Penetrating Radar (GPR) delivers what traditional methods cannot: an accurate, real-time visualization of what’s below the surface. The result? Fewer costly accidents, faster timelines, stronger risk mitigation, and measurable compliance with industry regulations.

By integrating GPR into utility detection workflows, project managers gain unmatched visibility. This technology allows teams to operate more efficiently and avoid delays caused by unexpected utility strikes. In environments where every inch of ground matters and safety cannot be compromised, GPR offers indispensable clarity.

Standardizing GPR use across excavation, civil infrastructure, and utility service operations isn’t just a step forward—it transforms project delivery. The equipment is now advanced, mobile, and accessible, and offers scanning options that adapt to complex environments, from reinforced concrete slabs to densely packed soil conditions. The data output not only identifies utilities but also maps them in context, supporting integration with GIS systems and digital twins for sophisticated planning and long-term maintenance strategies.

Construction leaders already leveraging GPR report fewer project stoppages, reduced insurance claims from utility damage, and smoother inspections. The technology doesn’t just detect—it informs decisions with accurate, actionable insights.

Still relying on outdated or invasive methods? Consider how every scan with GPR contributes to a safer work environment, a more compliant site, and a more predictable bottom line.

Looking to improve your next construction project’s safety and efficiency? Contact our team to schedule a GPR utility survey and discover how we can help you locate hidden utilities accurately and safely.

Content ideas