Summary: Concrete coring creates round holes in concrete using diamond-tipped drills — perfect for installing pipes, HVAC, or testing structural integrity. Concrete cutting uses saws or wires to remove or reshape sections, ideal for creating doorways, trenches, or performing controlled demolition. Use coring for precision and minimal disruption; use cutting for speed and larger structural changes.

Not all concrete work ends with the pour. Once it cures, there’s often a need to modify, adapt, or remove parts of a structure-and that’s where techniques like concrete coring and concrete cutting come in. This guide breaks down the key differences between coring and cutting, explains when each method works best, and explores how professionals use these strategies to tailor hardened concrete to complex project needs.

Concrete, a composite of cement, water, and aggregates, forms the backbone of modern construction. Its compressive strength, durability, and versatility make it ideal for everything from foundations to bridges. But after it’s set, altering it isn’t a simple task. That’s why specialized methods-precise, efficient, and engineered for specific goals-are used to make adjustments without compromising structural integrity.

Whether you’re navigating building renovations, installing infrastructure systems, or cutting through slabs for access routes, understanding the distinct purposes of concrete coring and cutting helps ensure the right tool is applied to the job. Ready to dig into the details? Let’s differentiate these two techniques and identify where each delivers the best results.

The Backbone of Modern Infrastructure: Why Concrete Matters

Characteristics of Concrete as a Construction Material

Concrete stands as the most widely used man-made construction material on the planet. Its global consumption reaches approximately 30 billion tons annually, according to the Global Cement and Concrete Association (GCCA). The reasons behind this industrial-scale reliance stem from its unique composition and high-performance features.

- Compressive strength: Concrete can handle immense pressure. Typical residential mixes average 2,500 to 4,000 psi, with high-strength variants exceeding 10,000 psi for specialized applications like high-rise columns and bridges.

- Durability: Once cured, concrete resists environmental degradation. It withstands rain, temperature shifts, chemical exposures, and even fire, making it ideal for exposed structures.

- Plasticity before setting: In its initial phase, wet concrete molds easily into any shape. This flexibility allows for the casting of intricate forms and customized architectural elements.

- Thermal mass: Concrete naturally moderates indoor temperatures. Due to its density and thermal storage ability, it reduces heating and cooling loads when used effectively in building envelopes.

Steel reinforcement turns it from a brittle material into one capable of handling flexural loads. The combination-reinforced concrete-is the standard frame for highways, skyscrapers, airports, and dams.

Core Reasons for Modifying Concrete in Construction Projects

Despite its robustness, concrete is rarely installed perfectly from the start. Site adaptations, architectural revisions, or post-construction upgrades often demand modification. These interventions can target existing slabs, walls, or columns long after the concrete has fully cured.

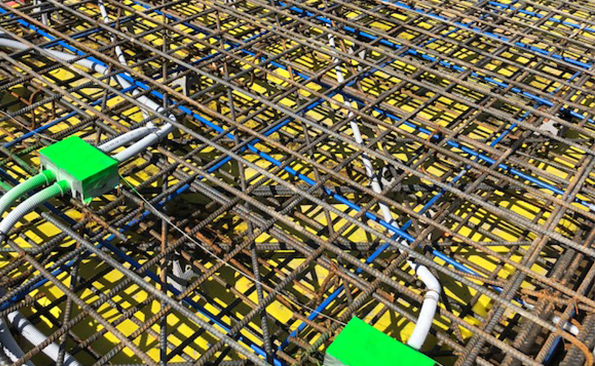

- Installing utilities post-pour: Need to run new electrical conduit or plumbing through a floor system? Coring delivers precise holes without compromising structural integrity.

- Retrofitting and renovations: When load requirements shift, or spaces get repurposed, cutting through concrete allows for realignment of structural pathways or complete slab removal-without dismantling the entire system.

- Quality control and analysis: Sometimes, engineers require core samples to test material composition and strength. It’s the only direct way to verify whether poured concrete meets design specifications.

- Demolition with precision: Modifying one component in a dense structural grid demands surgical accuracy. Broad demolition isn’t always an option; targeted coring and cutting make partial removal efficient and safe.

In every controlled modification, the goal remains the same: change concrete in-place without jeopardizing the broader structure. The moment design shifts or systems evolve, teams turn to either coring or cutting-two distinct techniques engineered for specific results.

What is the difference between concrete coring and concrete cutting?

Answer:

Concrete coring drills circular holes using a diamond-tipped core drill—ideal for utilities or structural testing. Concrete cutting uses saws to remove or reshape sections of concrete for demolition, doorways, or trenching.

What Is Concrete Coring and How Does It Work?

Concrete coring removes a precise, cylindrical piece of concrete-called a “core”-from a structure. Contractors use this method to create clean, round holes in walls, floors, ceilings, or slabs. These holes might serve as space for utility lines, HVAC systems, anchors, or structural analysis.

The method relies on a specialized tool known as a core drill. Powered by electricity, hydraulics, or pneumatics, the drill spins a hollow, cylindrical core bit embedded with industrial-grade diamonds along its cutting edge. These bits range in diameter from less than an inch to several feet, depending on project requirements. For large diameters, rigs are bolted into place to ensure stability during the drill process.

The Core Drill in Detail

Core drills operate with a combination of rotational force and steady pressure to pierce through dense material. Unlike percussion drills that fracture the concrete in a more aggressive manner, core drills remove material systematically, reducing stress on surrounding areas. This makes coring especially effective when there’s a need to preserve the surrounding structure or install precise penetrations without encouraging cracks.

Operators typically use water during coring to cool the bit, minimize dust, and create a smoother cut path. Wet coring is standard for most applications, whereas dry coring is limited to smaller diameters or where water cannot be used. Core extraction can occur in both vertical and horizontal positions, depending on where the hole is needed.

Where Coring Comes Into Play

- Running conduit, plumbing, or rebar through concrete slabs

- Extracting core samples for strength testing or forensic analysis

- Creating access points in reinforced concrete for retrofitting or renovation projects

Coring enables precise, low-vibration penetration through both reinforced and unreinforced concrete, brick, stone, and even asphalt. The level of control it provides means coring doesn’t just create holes-it shapes infrastructure to accommodate modern systems without compromising structural stability.

Question:

When should I use concrete coring?

Answer:

Use concrete coring when you need a round, precise hole in a wall, floor, or ceiling—especially for HVAC, plumbing, or electrical access.

What Is Concrete Cutting and How It Works

Concrete cutting is a precision process used to modify or remove concrete by using high-powered saws, blades, or wires. Unlike coring, which involves extracting cylindrical samples, cutting targets linear sections and larger surface  removals. Crews perform cuts for a variety of construction and demolition functions, ranging from expansion joints to full-depth slab extractions.

removals. Crews perform cuts for a variety of construction and demolition functions, ranging from expansion joints to full-depth slab extractions.

The Components of a Concrete Cutting Operation

Most concrete cutting projects rely on saws outfitted with industrial-grade diamond blades or abrasive wheels. These blades slice through concrete, reinforced steel, asphalt, brick, and masonry with consistent accuracy. The cutting tools vary widely depending on the job’s scale, depth requirements, and environmental conditions.

- Flat saws-also called slab saws-cut horizontally through floors, pavement, or bridge decks. Powered by gas, diesel, or electric motors, these machines guide thin, durable blades across the concrete surface at variable depths.

- Wall saws mount to vertical or inclined surfaces and use circular diamond blades to cut precise openings for doors, windows, elevators, or HVAC penetrations.

- Wire saws consist of cables embedded with diamond segments, ideal for cutting thick walls, columns, or irregular shapes that large blades can’t access directly.

- Handheld saws offer maneuverability in tight spaces or controlled demolition zones. With the right blade, operators make rapid plunge cuts or detailed trimming passes.

In all formats, lubrication plays a critical role. Water is usually applied during cutting to cool the blade, suppress dust, and minimize vibration. Dry cutting is used selectively-often with vacuum extraction systems-when water isn’t feasible due to location or material constraints.

Why Choose Cutting Over Other Methods?

When speed, edge accuracy, and structural adaptability are priorities, cutting provides unmatched control. It enables clean removal lines for patching, expansion control, or utility access. In commercial renovations or infrastructure upgrades, cutting also accommodates minimal disruption by eliminating the need for full demolition.

Ready to dive deeper into how coring and cutting compare side by side? Let’s break down those distinctions next.

Concrete Coring vs. Concrete Cutting – Where the Techniques Diverge and How to Choose

Differentiation of Coring and Cutting Techniques

Both concrete coring and concrete cutting reshape or modify concrete structures, but the methods, outcomes, and use cases vary significantly.

Concrete coring creates cylindrical holes. Technicians use diamond-tipped core drills to bore through concrete slabs, walls, or ceilings, typically to allow the installation of utility lines, pipes, or HVAC ducting. Coring is non-destructive beyond the bored cylinder, maintaining the structural integrity of surrounding material.

Concrete cutting, on the other hand, involves slicing through larger sections of concrete using flat saws, wall saws, wire saws, or hand saws. This process removes segments entirely and is used in demolition, expansion, or remodeling scenarios where partial or full removal of concrete is the objective.

Situational Suitability: When to Use One Over the Other

The functional requirements of a project dictate the right method. When only a precise, circular opening is needed-especially to accommodate mechanical or electrical conduits-coring is the direct solution. Its precision minimizes collateral damage, and it’s ideal in tight or constrained environments.

Conversely, cutting works better when large openings, structural separations, or full removal of concrete surfaces is necessary. For example, removing a section of floor slab to install an elevator shaft or creating door or window openings in a load-bearing wall.

- Use coring to install plumbing or electrical lines vertically through floors or horizontally through walls.

- Use cutting to resize a structural element, demolish slabs, or open access for heavy machinery.

Think about the size of material removal needed: a hole less than 20 inches in diameter? Go with coring. Slicing out a 5-foot by 10-foot floor opening? Cutting equipment will get it done faster and more efficiently.

Project location also influences the choice. In confined interior spaces where vibration and dust must be minimized, coring offers quieter, cleaner operation. For outdoor demolition work, flat saws and wire saws can accommodate larger, faster cuts.

Question:

When is concrete cutting better than coring?

Answer:

Concrete cutting is better when you need to remove sections of concrete, such as opening up slabs, creating trenches, or resizing structural elements.

Inside the Toolbox: Precision Gear for Concrete Coring and Cutting

Inside the Toolbox: Precision Gear for Concrete Coring and Cutting

Concrete presents an unforgiving surface, and working with it demands specialized tools engineered for high performance, reliability, and durability. The equipment selected directly influences efficiency, outcome precision, and the ability to meet structural and engineering demands. Below is a breakdown of the most commonly used tools and how they align with either coring or cutting applications.

Drills and Bits for Concrete Coring

Concrete coring relies on rotary drilling rigs paired with diamond-tipped core bits. These machines extract cylindrical samples or create openings with consistent diameters in walls, floors, and ceilings.

- Core Drills: Available in handheld, rig-mounted, or stand-mounted variants. Rig-mounted models, especially those with track support, offer the stability required for deep or large-diameter holes.

- Diamond Core Bits: Manufactured with industrial-grade diamonds embedded along the cutting edge. Diameters typically range from 1/2 inch to 60 inches, with common sizes falling between 2 and 14 inches.

- Water Supply Systems: Integrated water feeds cool the bit and suppress dust. This feature maintains cutting performance and extends bit life.

- Vacuum or Anchor Stands: Provide mounting support on vertical or inverted surfaces where standard rigs can’t be stabilized by gravity.

For deep coring-common in utility penetrations for HVAC, electrical conduits, or plumbing-hydraulic or high-powered electric models dominate on construction sites.

Saws and Blades for Concrete Cutting

Concrete cutting spans flat surfaces, reinforced walls, beams, and bridge decks, each scenario dictating a specific machine and blade type.

- Flat Saws (Slab Saws): Designed for horizontal surfaces. Walk-behind units powered by gasoline, diesel, or electric motors can cut depths beyond 24 inches with the appropriate blade.

- Wall Saws: Track-mounted and ideal for vertical or inclined surfaces. These saws excel at precision cuts in structural elements like retaining walls and stairwell openings.

- Wire Saws: Used where standard saws are ineffective, such as in mass concrete or irregularly shaped structures. They utilize a wire laced with diamond beads that wraps around the structure to make extensive cuts.

- Handheld Cut-Off Saws: Useful for quick cuts or work in confined areas. Fitted with abrasive or diamond blades ranging from 12 to 16 inches in diameter.

Blade composition significantly affects cut quality and lifespan. Segment height, diamond matrix formulation, and bond type must align with the specific compressive strength and aggregate composition of the concrete being cut.

Matching Equipment to Task Requirements

Choosing between coring and cutting tools hinges on two variables: the structural objective and the concrete’s physical characteristics. For penetration with minimal impact to the adjoining matrix, core drills outperform saws. When linear separation or material removal is needed, various saws-each designed for cut geometry and depth-deliver cleaner, faster results.

How deep is the cut? Is the concrete reinforced or hollow? Does the equipment need to function in low-noise or wet environments? These questions shape the equipment selection process more than the size of the job alone.

Experienced contractors evaluate torque output, rpm ratings, cooling systems, and material resistance before assigning tools to a job. Sometimes that means combining systems: using wire saws to remove sections after drilling precise core points to define cut parameters.

Where Concrete Coring Gets to Work: Real-World Applications

Creating Precision Openings for Building Systems

Concrete coring excels when clean, round holes are needed to install mechanical, electrical, and plumbing systems. Core drills remove cylindrical sections from hardened concrete without damaging the surrounding structure. This makes it the preferred method for:

- Plumbing Systems: Coring penetrates walls, slabs, and floors to accommodate pipes of various diameters, from small sinks to large-diameter stormwater drains.

- Electrical Infrastructure: Electricians use core drilling to create access channels for conduit runs, transformer hookups, and switchgear installations in both new builds and retrofits.

- HVAC Installations: Circular openings made by coring accommodate ductwork, ventilation shafts, and air handling systems without overcutting or structural compromise.

Contractors favor coring in these scenarios because linear cutting tools would struggle to shape smooth, circular holes. Coring also reduces dust and vibration, keeping job sites cleaner and preserving concrete integrity.

Extracting Concrete Samples for Structural Testing

Structural engineers rely on concrete coring to collect samples for compressive strength testing, void analysis, or chemical composition evaluation. Each core reveals critical data about how a structure will perform under load or environmental stress.

Testing agencies follow ASTM C42 / C42M standards when extracting cores. These samples typically measure between 3 and 6 inches in diameter and are drilled to a depth sufficient to capture the full cross-section of the element. The information obtained helps verify mix quality, check for proper consolidation, or assess aging in existing structures.

This technique also aids forensic investigations. When failure occurs, coring can locate hidden defects like internal cracking, chloride penetration, or alkali-silica reaction zones not visible from the surface.

Still curious how coring supports your next project plan or inspection protocol? Start by assessing which building systems require precise penetration or if there’s a need to study the material itself.

Practical Applications of Concrete Cutting

Creating Openings in Walls, Floors, and Ceilings

Concrete cutting plays a central role when modifying existing structures to accommodate new utilities, doorways, stairwells, or mechanical systems. Builders and contractors rely on this technique to carve clean openings in reinforced slabs, foundation walls, or vertical panels without compromising surrounding structural integrity.

Circular saws and wall saws equipped with diamond blades allow crews to cut through heavily reinforced concrete with a high degree of dimensional accuracy. For example, wall saws mounted on guide rails can create new window or ventilation openings with precision tolerances under 2 mm, eliminating the need for manual chiseling or overcutting.

Floor modifications for elevators, ductwork, and plumbing chases often require flush cuts through post-tensioned slabs. Using slab saws-also known as flat saws-operators can execute horizontal cuts while maintaining the concrete’s load-bearing capacity. This method is indispensable in adaptive reuse projects, retrofits, and commercial remodeling.

Making Precise Adjustments to Concrete Structures

When concrete elements exceed tolerance limits or need structural reliefs, saw cutting provides the most controlled removal method. Contractors use cutting not only for demolition but also for resizing, trimming, or reshaping elements such as beams, curbs, and architectural features.

- Trenching and Utility Access: In roadway and sidewalk modifications, concrete cutting provides neat trenches for underground conduits or drainage systems. Unlike breaking or jackhammering, saw cutting keeps trench walls clean, vastly reducing backfill and patching time.

- Control Joint Formation: To prevent random cracking during curing, saw cutting introduces control joints at calculated intervals. These cuts are typically made within 6 to 18 hours of placement, depending on slab thickness and ambient conditions.

- Selective Demolition: In renovation work, precision saws enable partial removal of structural elements while preserving adjacent surfaces. For instance, bridge deck replacements often involve longitudinal cuts to isolate the damaged section before replacement.

In infrastructure-heavy applications, such as subway tunnel expansions or airport terminal upgrades, diamond wire saws and track-mounted equipment provide flexibility to slice through reinforced pylons or barrier walls in constrained environments. This versatility makes concrete cutting an essential solution for high-precision excavation and retrofitting challenges.

Concrete Coring: Pinpoint Precision and Practical Boundaries

Concrete coring delivers unmatched accuracy for creating circular openings in structural and non-structural elements. From mechanical penetrations to plumbing access, this method excels in projects where alignment and finish matter. However, it isn’t universally applicable across all use cases. Explore where it shines-and where it stops short.

Key Advantages of Concrete Coring

- Clean, Circular Openings: Diamond-tipped coring equipment produces smooth, perfectly round holes with minimal surface disruption. It’s particularly effective for HVAC ducts, electrical conduits, or pipe installations where geometric consistency is essential.

- Minimal Vibration: Unlike impact-based methods, coring induces low vibration levels, reducing the risk of structural fractures around the work area. This makes it suitable for retrofits in occupied buildings and sensitive environments such as hospitals, labs, or historical sites.

- Quiet Operation: Wet rotary coring systems generate considerably less noise than saw cutting or jackhammer methods. This can improve onsite working conditions and contribute to compliance with local noise ordinances.

- Dust Control: Wet coring captures most of the particulate matter with water cooling systems, significantly reducing airborne dust-an advantage for indoor use and air-quality-sensitive projects.

Limitations to Consider

- Depth Constraints: Core drilling depth typically maxes out around 60 inches with standard equipment. Beyond that, custom setups or large-diameter rigs become necessary, which can escalate project costs and setup time.

- Slower for Large-Scale Removal: In jobs requiring mass concrete removal rather than precision openings, coring is not time-efficient. Wall sawing or flat saw cutting offers faster progress for large sections.

- Limited Shape Flexibility: Coring only produces circular holes. If the project demands a square or irregular-shaped penetration, concrete cutting provides greater form versatility.

- Access Requirements: Core drilling equipment usually needs direct access to the work face. In tight or vertical spaces, rig anchoring and positioning may require additional logistical planning.

Think about your project’s scope. Does it involve precise circular cuts within a confined space? Concrete coring will meet that need with accuracy. But if you’re chasing length, deep cuts, or odd shapes, coring alone won’t suffice. What does your blueprint demand?

Concrete Cutting: Strengths That Drive Efficiency-and Where It Falls Short

Concrete cutting delivers speed, adaptability, and scale-qualities that make it the preferred choice for many large surface projects. From roadways to warehouse floors, when the goal is to create long linear cuts or open up expansive concrete panels fast, cutting does it better than coring.

Advantages of Concrete Cutting

- High-speed execution: When time matters, concrete cutting reduces project timelines. Diamond blade saws and wall saws can slice through several inches of concrete in seconds, depending on power and blade size. Floor saws, for example, can operate at speeds exceeding 25 feet per minute under optimal conditions.

- Wide range of applications: Contractors use cutting methods like flat sawing, wall sawing, and wire sawing across commercial, industrial, and residential projects. This flexibility allows for trenching, expansion joint shaping, and slab removal with a single technique.

- Minimal vibration and noise (with the right setup): Compared to jackhammers or impact tools, cutting with diamond-tipped blades or water-cooled systems significantly reduces structural disturbance. This is critical in hospitals, laboratories, and active commercial buildings.

- Clean, linear cuts: Saws produce sharp edges that support precision demolition and allow for seamless reconstruction or retrofitting of concrete structures.

Limitations of Concrete Cutting

- Lack of precision for cylindrical openings: Need a round opening for a pipe, conduit, or HVAC duct? Cutting won’t provide the same accuracy. While circular shapes can be approximated with multiple linear cuts, the result lacks structural clarity and clean-edge profiling. Coring delivers superior results in these scenarios.

- Access and blade size constraints: Wall saws and floor saws require enough clearance to maneuver. In tight or overhead areas, setup may be challenging or outright infeasible without significant preparation or modified equipment.

- Cutting depth limitations: While large-diameter blades can reach impressive depths, typically 24 to 36 inches, not all machinery supports such specifications. For deeper sectional removals, wire sawing or multiple passes may become necessary, increasing time and effort.

Concrete cutting thrives where speed and surface coverage matter, especially in infrastructure and demolition projects. Yet, when dimensional precision or confined access is critical, the method shows its limits.

Staying Safe on the Job: What You Need to Know About Concrete Coring and Cutting

Personal Protective Equipment (PPE): Not Optional, Always Necessary

Concrete dust lingers in the air, cutting blades spin at thousands of revolutions per minute, and high-pressure drills bore into solid slabs-this is not an environment for half-measures. When performing coring or cutting, failing to wear the correct PPE directly increases the risk of injury.

At a minimum, every operator and nearby worker must use:

- Respiratory protection – NIOSH-approved particulate respirators prevent inhalation of silica dust, a known cause of silicosis. In 2023, OSHA reaffirmed the permissible exposure limit for respirable crystalline silica at 50 %u03BCg/m³ over an 8-hour shift.

- Eye and face protection – Safety goggles with side shields and full-face shields intercept flying debris and slurry spray from high-speed cutting tools.

- Hearing protection – Core drills and wall saws produce sound levels above 100 dBA. Exposure beyond 15 minutes requires earplugs or earmuffs rated for high decibel environments.

- Hand protection – Cut-resistant gloves reduce the likelihood of lacerations during blade handling or manual positioning of coring rigs.

- Foot and leg protection – Steel-toed boots with puncture-resistant soles, combined with shin guards when necessary, protect against falling cores, blade slips, and exposed rebar.

Mastering Equipment Handling and Creating a Controlled Workspace

The difference between professional execution and preventable accidents lies in how equipment is handled and how the workspace is maintained. Operators must be trained on the specific tool-whether it’s a handheld saw, track-mounted wall saw, or core drill rig-as improper use leads to kickbacks, binding, and uncontrolled movements.

Setup matters. Coring rigs should be bolted or vacuum-mounted to the slab. Loose rigs shift mid-operation and can cause misalignment or sudden breaks in torque. For cutting applications, blade type and rotation speed must match the substrate to prevent overheating or shattering.

Beyond the equipment itself, the workspace requires continuous attention:

- Water control – Use wet-cutting techniques to suppress dust and coolant flow to extend blade life. Direct slurry into designated containment systems to avoid slip hazards and environmental contamination.

- Barriers and signage – Isolate the cutting or coring zone using cones, tape, or physical barriers. Display warning signs to deter untrained personnel from entering active areas.

- Cable and hose management – Route power cords and water lines away from walking paths and blade paths. Use protective covers or hangers to prevent tripping or accidental tool disconnection.

- Ventilation – In enclosed or poorly ventilated settings, portable exhaust fans or HEPA-filter air scrubbers reduce dust concentration and maintain safe air quality thresholds.

Concrete coring and cutting don’t tolerate carelessness. Each action requires pre-planning, awareness, and consistent execution. What does your current safety setup look like? If it’s not methodical, it’s not safe.

Cost Showdown: Concrete Coring vs. Cutting

Breaking Down the Price Factors

Whether you choose coring or cutting, the cost profile changes significantly depending on a few key elements. Equipment requirements shape the baseline expense-core drills use diamond-tipped bits that carry a steeper upfront cost than many flat saw blades. While a high-quality drilling rig for coring may exceed $10,000, a walk-behind concrete saw for cutting generally starts around $2,500. Tool maintenance and wear also diverge; drill bits wear out faster when boring deep holes through reinforced concrete, which pushes recurring expenses higher.

Labor plays an equally decisive role. Coring often requires precision, specialized operators, and sometimes more setup time. Cutting tends to be faster in open spaces but requires significant dust control and debris management, which can extend project hours. According to 2023 cost data from RSMeans, coring services typically range from $12 to $45 per hole, depending on diameter and depth, whereas cutting costs vary from $2 to $10 per linear foot based on slab thickness and rebar content.

Project Size and Complexity Multiply the Gap

For a single hole through a concrete wall, coring costs stay manageable. The scales tip, however, on projects involving dozens of penetrations-such as mechanical retrofits in high-rises-because cumulative wear on coring bits increases overall material cost. Cutting, on the other hand, grows more efficient per linear foot as square footage expands. A large-scale slab demolition often sees cutting costs reduced by 10-15% due to economies of scale.

In highly reinforced concrete, coring also becomes slower and more expensive because it requires slower drill rates and cooling water to manage friction. Cutting, especially with deep or embedded rebar, may demand specialized saws and blades-driving up the estimate.

Time Horizon: Short-Term Spend vs. Long-Term Value

Immediate cost per action doesn’t always reflect true value. Coring’s higher precision reduces the chance of collateral damage-so there’s less need for patchwork or structural reinforcement afterward. This can shrink post-installation repair budgets by 5-20% depending on structural exposure. Cutting, faster and more affordable upfront, may create wider kerfs or unintended micro-cracking in adjacent zones, especially in non-prestressed slabs. The cost of remediating those issues may offset initial savings.

So ask yourself: is it a one-time cut on a flat surface, or an intricate job with multiple penetrations needing accurate alignment? Depending on your answer, one method delivers better ROI over the full lifecycle.

- Need deep, circular penetrations? Factor higher equipment and labor costs for coring-but offset with fewer repairs needed post-installation.

- Removing long sections of flooring or sidewalk? Cutting wins on square-foot pricing and speed, especially in large-scale applications.

- Working in tight or vertical spaces? Costs multiply for both, but labor complexity often gives coring the higher quote.

Budgeting for concrete modification means looking beyond the per-unit rates and asking: what are the cascading costs or savings this technique creates across the whole job?

Making the Right Call: How to Choose Between Concrete Coring and Cutting

Assessing Your Project’s Specific Needs

Before selecting between concrete coring and concrete cutting, start by reviewing the project’s primary goals. Does the job require a precise circular opening for a utility line, or a linear separation for expansion joints or demolition?

Project specifications will dictate the method. For example:

- Concrete Coring suits situations where round openings for plumbing, HVAC, or electrical conduit are needed without impacting surrounding concrete surfaces.

- Concrete Cutting handles slab separation, wall removal, or trench cutting with scalable precision across horizontal and vertical surfaces.

Thinking in Terms of Structure and Output

Coring removes a cylinder of material without creating significant stress fractures around the hole. It’s the go-to for post-tensioned slabs or structurally sensitive concrete. Cutting, on the other hand, distributes force differently and works better for controlled demolition or large-scale sectioning.

Ask these questions:

- Does the structural design permit lateral stress from blade passes?

- Are the cuts or holes intended to accommodate incised shapes or pre-cast fixtures?

- Will ongoing operations around the site allow for water-cooled equipment or require dry methods?

Efficiency and Access Matter

Time limitations and access points often determine the appropriate method. Wall saws may require stable vertical access, whereas core drills can operate horizontally, vertically, or even upside down in confined areas. If debris control or noise levels are critical, coring-typically quieter and producing less dust-might give the edge.

Additionally, when you face reinforced concrete areas with embedded rebar, both coring and cutting can manage the task, but coring offers cleaner edges and minimizes damage to the adjacent surface.

Summary of Use Cases Based on Project Type

- Use Concrete Coring for: HVAC routing, manhole access, dowel installations, telecom conduits, laboratory equipment anchoring.

- Use Concrete Cutting for: Roadway panel replacement, curb removal, foundation trenching, large slab removal, building modifications.

Choosing between the two isn’t about better or worse-it’s about aligning the process with the outcome. Function drives form, and in concrete modification, method follows intent.

Mastering the Craft: Best Practices for Concrete Coring and Cutting

Prioritize Rigorous Equipment Maintenance

Precision depends heavily on machine performance. Core drills, wall saws, handheld and walk-behind saws-each tool demands strict upkeep. Dull or damaged blades lead to ragged edges, overheating, and unnecessary downtime. Use  the manufacturer’s service intervals as non-negotiable benchmarks, not polite suggestions. For example:

the manufacturer’s service intervals as non-negotiable benchmarks, not polite suggestions. For example:

- Inspect diamond segments on blades and bits before and after each use; look for excessive wear or bonding loss.

- Ensure coolant systems function properly to prevent overheating during deep cuts or prolonged coring sessions.

- Check motor performance frequently, especially in high-power equipment used on reinforced concrete.

Cleaning the machinery after each job removes slurry and fine dust that corrodes components. Store gear in a climate-controlled environment to protect motors and electronics from moisture and temperature fluctuations.

Use Technique to Guide Precision, Not Force

Clean cuts and cores emerge from consistency, not pressure. When cutting, allow the blade to work at its own rate; forcing progress increases vibration and trajectory deviation. Begin with shallow passes to establish control and line accuracy. Gradual depth increases prevent blade deflection and material blowout.

In coring, start with a positioning guide-a simple anchor or pilot hole centers the bit and eliminates walking. Apply steady, even pressure. Intermittently ease off the drive to clear debris from the bit, especially during large-diameter or deep holes where sludge accumulation can seize the core barrel.

Set Up to Succeed

Layout and preparation influence outcomes as much as the cut itself. Align your logistical setup with the end goals:

- Mark cut lines or core centers with high-visibility chalk, using laser levels when precision alignment matters.

- Review structure plans to avoid hitting post-tension cables, embedded utilities, or rebar clusters; GPR scans provide actionable clarity.

- Secure workpieces and power sources-stability eliminates vibration-induced deviations during operation.

Monitor, Adjust, Repeat

Experienced crews don’t lock into a single method. They adapt cut speed as aggregate density changes or reposition equipment if slurry buildup affects line visibility. Real-time adjustment separates sloppy from surgical. Use continuous feedback-sight, sound, vibration-as performance indicators. It’s a live process, not set-and-forget.

Balancing Precision and Planet: Environmental Impact and Sustainability Considerations

Waste Management During Coring and Cutting

Concrete modification generates significant waste – both in raw material and energy use. During coring, the primary byproduct includes cylindrical concrete cores and slurry produced by wet drilling. Cutting, especially with wet saws or wall saws, also produces slurry along with larger debris and offcuts. Without proper containment, this waste can clog drains and leach harmful particles into soil or waterways.

Handling these materials effectively starts with containment. Vacuum systems equipped with HEPA filters gather dust and slurry at the source. For instance, a core drill using wet cutting techniques paired with a vacuum slurry collector can capture over 90% of particulates before dispersion. On job sites near sensitive areas such as hospitals, data centers, or occupied buildings, these systems aren’t optional – they’re standard protocol to maintain indoor air quality and prevent structural contamination.

After collection, waste needs classification. Slurry from concrete cutting often contains silica, calcium hydroxide, and trace metals. Disposal teams neutralize and dewater this waste through filtration presses or chemical treatments, converting it to filter cake – a semi-solid substance easier to transport and dispose of through approved landfills. Some operations funnel it into recycling systems where constituents like sand and residual cement are reused.

Sustainable Practices for Reducing Environmental Impact

Concrete coring and cutting operations consume electricity, water, and tool wear materials. Cutting-edge practices in sustainability focus on reducing these inputs while extending the life cycle of each tool and component.

- Tool Longevity: Using diamond-tipped blades or core bits increases efficiency and decreases waste. These wear-resistant tools can last up to 10 times longer than abrasive cutters, reducing metal waste and lowering overall carbon footprint per project.

- Local Water Recirculation: Wet cutting requires substantial water flow. Operators now integrate recirculation systems that capture, filter, and reuse water, cutting consumption by up to 80% compared to standard hook-up methods.

- Battery-Powered Equipment: Moving away from gas-powered saws and drills trims CO2 emissions significantly. A fully electric setup powered by grid electricity or portable solar units enables silent, clean operation even in urban environments.

- Material Reuse: Recovered concrete cores from coring jobs may be repurposed as aggregate. Crushing and reintegrating these materials into new concrete reduces mining demand for virgin aggregate and lowers transportation emissions.

Implementing these sustainable approaches doesn’t just minimize footprint-it drives compliance and cost efficiencies. Want to know what level of dust your next project will generate? Measure particulate concentration with real-time air monitoring stations and adjust suppression measures accordingly. Sustainability in coring and cutting isn’t theoretical-it’s measurable, tangible, and growing industry-wide.

Navigating Regulatory and Compliance Issues in Concrete Coring and Cutting

Each concrete modification project falls under the scope of regional construction regulations and national safety laws-ignoring these is not an option. Whether the job involves coring precise openings through foundation slabs or slicing structural concrete to reconfigure wall layouts, regulatory compliance defines the parameters of what can and cannot be done on-site.

Adherence to Local Construction Codes

Construction codes vary significantly by jurisdiction, but all codes converge around one goal: structural integrity. When coring into load-bearing columns or cutting through beams and slabs, contractors must reference the International Building Code (IBC) or its local equivalent to avoid compromising the overall structural performance. In many cities, cutting beyond a specified depth requires structural calculation reports or engineer-stamped drawings, especially in high-rise or commercial properties.

Permits may be required before starting the work. For instance, Los Angeles mandates a plan check and approval process for any structural modification involving core drilling in seismic zones. Violating these procedures triggers penalties or stop-work orders-not speculative outcomes but documented realities in municipal enforcement records.

Compliance with Safety and Environmental Regulations

Operating coring and cutting equipment produces silica dust, noise, vibrations, and waste slurry. Agencies like OSHA in the U.S. enforce strict exposure limits for respirable crystalline silica (50 µg/m³ over an 8-hour time-weighted average), which means wet methods or vacuum extraction systems must accompany most concrete-cutting activities.

Contractors also have to factor in EPA regulations for wastewater disposal. Wet cutting generates slurry that requires containment and treatment before release into drainage systems. Many municipalities, including New York City and Chicago, impose fines for unfiltered slurry discharge into storm drains.

- OSHA Standard 1926.1153 governs permissible exposure to silica during cutting, drilling, and grinding of concrete.

- EPA 40 CFR Part 122 outlines necessary control measures for construction site runoff and discharge.

- State-specific standards, such as Cal/OSHA Title 8 Section 1530.1, exceed federal requirements in silicon dust control.

Additionally, noise created during slab saw cutting or wall sawing can exceed 85 dB(A), triggering regulatory thresholds that require the use of hearing protection and engineered controls. In dense urban areas, work-hour restrictions and decibel caps may apply, enforced by local Departments of Environmental Protection or Building Departments.

What happens if these standards are not followed? Agencies issue citations, levy fines, and can even shut down operations. These aren’t hypothetical risks-they’re regulatory tools that shape the entire concrete modification industry. Both coring and cutting must operate within this framework, or projects grind to a halt.

So before deploying a core rig across a bridge deck or firing up a slab saw on a hospital renovation project, review the latest code amendments and environmental guidance. Working without that knowledge isn’t just a gamble-it guarantees a compliance failure.

Real-World Applications: How Coring and Cutting Shape Construction Projects

High-Rise Retrofit – Core Samples to Guide Structural Reinforcement

During a seismic upgrade to a 28-story commercial tower in downtown Seattle, structural engineers turned to concrete coring to validate the original rebar layout shown in outdated construction drawings. Using 6-inch diameter core drills, teams extracted over 40 cylindrical samples from beams, columns, and floor slabs across several floors. These samples enabled compressive strength testing and petrographic analysis.

The results uncovered areas with inconsistent concrete density and unexpectedly shallow coverage over rebar. Based on the findings, the engineering team adjusted the retrofit plan, increasing anchor lengths and changing anchor placement in five of the lower floors. The use of coring avoided costly demolition and provided data-driven decisions for reinforcement.

Bridge Deck Replacement – Precision Cutting for Segment Removal

On a state highway project in Illinois, a 1960s-era bridge deck required partial replacement after chloride-induced deterioration compromised its integrity. Rather than full demolition, contractors used concrete cutting via wall saws and slab saws to isolate and remove only the damaged sections.

Crew members created longitudinal and transverse cuts that penetrated up to 18 inches deep. Each segment, weighing between 1,000 and 3,000 pounds, was lifted by crane from the remaining structure. This method dramatically reduced disruption to vehicle traffic and preserved the underlying girders.

The final report showed a 30% reduction in labor hours and a 15% reduction in projected material waste when compared to total deck removal.

Hospital Mechanical Upgrade – Five-Foot Core Openings for Duct Penetration

In Florida, a 196-bed medical center required new HVAC ducts to feed isolated patient zones. The design called for roughly two dozen new vertical service chases between mechanical rooms and surgical suites. To execute the plan within a functioning hospital environment, contractors relied on large-diameter concrete coring.

Using custom rigs, operators cored 60-inch diameter holes through 10-inch post-tensioned slabs spaced across six floors. Water-cooled diamond coring rigs prevented dust generation-a critical factor in clinical spaces. Infection control teams monitored microbial levels daily, and no contamination was noted throughout the 8-week procedure.

Urban Plaza Renovation – Decorative Cuts to Integrate Lighting Features

A civic landscape improvement project in Boston included creating geometric lighting inlays around a newly poured concrete plaza. Rather than casting conduit tubing during the initial pour, designers used dry concrete cutting to achieve crisp patterns that housed LED strip lighting.

Crews executed 1.25-inch wide cuts in 9-inch thick concrete, following CAD-generated linework, including arcs and intersections. Hand-held saws paired with vacuum attachments prevented both fracture and dust dispersal. The result maintained architectural integrity while enabling quick retrofitting of over 700 feet of lighting conduit.

Lessons from the Field

- Data beats assumption: On the Seattle retrofit, coring uncovered undocumented design flaws-proving that visual inspection alone can’t confirm structural integrity.

- Precision saves time and material: Controlled cutting during the bridge project minimized unnecessary removal and reduced traffic closure times significantly.

- Environment-specific techniques matter: Coring in hospitals required water-cooled, low-vibration tools; without them, construction would have compromised patient safety.

- Post-cure cutting opens design flexibility: In Boston, dry cutting allowed for aesthetic upgrades well after initial curing, without undermining the slab’s strength.

Choosing the Right Cut: Coring or Cutting?

Concrete coring and concrete cutting serve distinct roles in construction and renovation, and knowing when to use each transforms efficiency and accuracy on site. Coring removes precise, cylindrical sections of concrete, perfect for mechanical penetrations like electrical conduits or HVAC intake points. Cutting, on the other hand, creates linear separations-seamless floor expansions, wall openings, or slab removals.

Review the nature of the structure and the outcome required. Need a round opening? Diamond core drilling handles it with minimal impact to surrounding material. Facing the task of removing an entire section of wall or floor? Flat sawing or wire sawing clears the way. The intended result dictates the method-nothing more, nothing less.

Take this forward. Evaluate your project’s structural requirements, access limitations, and performance expectations. Choose a method based not on habit, but on what the job demands. The right technique, applied at the right time, always delivers cleaner finishes, faster timelines, and fewer surprises.

Go Deeper: References and Further Reading

Ready to explore the engineering behind concrete modification in more detail? The following resources offer technical insights, real-world applications, and in-depth comparisons between concrete coring and cutting. Whether you’re a contractor, project manager, or simply curious about where to dig deeper, these references will take you there.

Industry Standards and Guidelines

- American Concrete Institute (ACI) – www.concrete.org. Contains technical documents such as ACI 214R-11 and ACI 544.4R for performance grading and modifications to existing concrete structures.

- Occupational Safety and Health Administration (OSHA) – Visit www.osha.gov/construction for safety procedures on concrete cutting and coring, specifically standards 1926.702 and 1926.21.

Manufacturer Guides and Tool Specifications

- Husqvarna Construction Products – Offers application notes, machine guides, and concrete cutting charts. See their technical library: www.husqvarnacp.com.

- Hilti North America – Explore technical data sheets and field applications for core drills and saws at www.hilti.com.

Concrete Coring and Cutting Associations

- CSDA – Concrete Sawing & Drilling Association – Provides training, specifications, tool operation manuals, and method comparisons. Access their online resources: www.csda.org.

- International Concrete Repair Institute (ICRI) – In-depth study results on structural modification techniques, including selective coring and structural sawing. Visit www.icri.org.

Technical Publications and Journals

- Construction and Building Materials (Elsevier) – Peer-reviewed articles on concrete behavior, material analysis, and impact of mechanical operations like coring/cutting. Browse issues at ScienceDirect.

- ACI Materials Journal – Research documentation on structural alterations using precision cutting tools. Look into studies referenced at www.concrete.org.

Further Learning and Certification

- CSDA Training Programs – Contractor certification programs covering diamond cutting basics, advanced sawing techniques, and coring best practices. Register through CSDA Training.

- National Institute for Certification in Engineering Technologies (NICET) – Certification in construction materials testing that includes modules on concrete installation and modification. See more at www.nicet.org.