Concrete Scanning Using GPR to Save Your Firm Time and Money

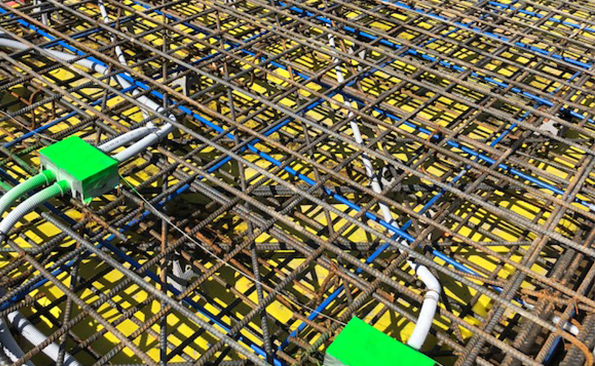

As construction processes, equipment and techniques evolve, technology plays an ever-increasing role in the efficiency, safety, and efficacy of modern construction. One major advance is the use of ground-penetrating radar (GPR). These devices are often used to locate reinforcing steel members such as rebar, post-tensioning cables and steel mesh in concrete floors, walls and bridge decks, utility conduits laid beneath or within a building slab, significant air voids, and similar potential obstacles. In 2020, GPR has become the gold standard in utility and reinforcement location, surpassing X-ray evaluation in many cases as the preferred nondestructive scanning method for construction sites all over the world.

Safe2Core offers concrete scanning services and other subsurface investigation modalities in major metropolitan areas including:

Scanning, Sawing and More—With Confidence

When it comes to locating what’s under a slab or the earth, Safe2Core is second to none. Safe2Core has an enviable safety record and unparalleled client satisfaction in the markets we serve. We have become the “go-to” utility location and concrete inspection service for many of the West Coast’s largest and best-known contractors. From scanning and other nondestructive testing and locating services, to coring and sawing, to in-ground CCTV pipe and conduit inspections, we are proud to lead the way in this field with the latest technology and certifications, backed by over 40 years of combined experience in the field and staffed with people who understand the vital importance of doing the job right the first time, every time. When it comes to knowing what lies beneath the floor or behind the walls of your project, don’t leave it to chance and guesswork. Contact Safe2Core so your crew can work with confidence!

Frequently Asked Questions (FAQ)

Question: How does concrete scanning using GPR work? –Roger, Oakland, CA

Answer: Ground-penetrating radar scanning rigs generally come in two types: a pushcart-style testing module or a smaller device which uses probes set into the ground surface at set intervals. Both devices work by pushing radio waves into the ground and “reading” what lies beneath. This scan data allows us to see 2D or 3D images of the area being tested without expensive and risky excavating or exploratory coring. These images are then used as part of the site’s data acquisition program to plan projects such as:

- Subsurface utility engineering

- Core drilling for QC and QA

- Concrete cutting

- Private utility locating

- Post-project QA such as concrete assessment of conditions below the concrete surface, thickness and overall integrity of the slab

- Pre-work planning to help locate and avoid hidden objects within concrete slabs which may lead to utility damage, allowing contractors to minimize the risk of costly repairs

- And more

Question: Why is concrete scanning important? How much does a concrete scan cost? –Quincy, Brownsville, TX

Answer: The cost of a specific concrete scanning project varies based on a number of factors. Some include the timeframe, size, location, special safety protocols and considerations. These can cause the price of testing to fluctuate somewhat. However, a concrete scan can save your company thousands or tens of thousands of dollars in lost time, productivity and unnecessary repairs. You presumably have access to the drawings, but what do you do if you need to cut, drill, or core into concrete? Do you know if there’s anything underneath which might require specialized equipment to deal with or extra care to avoid, such as conduits and pipes? What are the ramifications if one of these pipes were cut or drilled? Can you afford to play a guessing game? The information concrete scanning provides is where the real importance of a concrete scan comes into play, because forewarned is forearmed, as they say.

Question: How long does it take to scan an area for core drilling? –Tricia, San Jose, CA

Answer: It depends on the scope, scale and size of the project, as well as the ambient environment and composition of the underlying material. A bridge deck will certainly take longer than a house pad, but might not take as long as an airport runway. There’s no such thing as a “typical” job in this line of work, so what may take a few hours in one location may chew up a full day or longer somewhere else. We are happy to give you a rough estimate, however!

Question: When should you choose concrete scanning? –Juan, West Palm Beach, FL

Answer: Concrete scanning with GPR has been proven to be one of the most effective and versatile ways to examine a slab and the underlying material. Unlike thermal imaging and X-rays, GPR can create both 2D and 3D images of the area being tested, giving contractors and project management more information so they can better direct the work. It is fairly rare that another method is better for a given project than GPR, but it does happen occasionally. If you’re unsure if GPR is right for your project, contact us!

Question: Can you locate utilities below the concrete slab? For example, can you locate electrical conduits made of PVC? –Matilda, Austin, TX

Answer: GPR is excellent for locating private utility lines, embedded object and leak detection below a slab-on-grade or in a concrete wall, among other things. Using the location information from the scan as well as the as-built documentation, we can usually pinpoint what we’re seeing and how best to work with or around it to minimize disruption of the slab as well as prevent damage to utility lines.

Question: Can ground-penetrating radar identify the difference between rebar, post-tension cables, electrical conduits, and other embedded materials? –Wayne, Palo Alto, CA

Answer: GPR can be used to locate rebar, conduit and other embedded or hidden objects and materials. However, by itself, GPR cannot tell us what we are seeing. It takes a combination of experience, understanding of the equipment and access to information like the site drawings, as-built and per-plan alterations, photographs and so on to be able to determine what the GPR is picking up. With technology such as GPS location so prevalent on construction sites now, it makes our job a lot easier because we can pinpoint where things are supposed to be and mark them for future reference.

Question: Are there any health risks associated with ground-penetrating radar, and is GPR noisy? –Tiffany, Anaheim, CA

Answer: GPR is one of the lowest-risk forms of nondestructive concrete testing. Because it uses polarized radio waves, there is no risk to humans simply from using the device or standing close to it. It doesn’t make any noise, so it’s a very unintrusive form of testing as well. Most of the risks associated with GPR involve improper lifting or ergonomic techniques, and even these are relatively minimal if good lifting and carrying practices are followed.

Question: How deep does GPR scan in concrete? –Bashir, Santa Ana, CA

Answer: This depends on the concrete slab thickness, the original mix design, the materials embedded in the concrete and the type and composition of the subgrade. Low-density materials such as shale may allow the signal to penetrate as deep as 100 feet (30m) into the earth. The presence of denser materials such as some clays in the subgrade, large quantities of reinforcing steel and utility lines and heavier mix designs may reduce this down to a few inches. In rare cases, we may need to augment our GPR testing with X-ray testing for confirmation purposes, something like getting a second opinion from a doctor.

Question: How fast can we get a concrete scanning and coring service? –Frederick, Austin, TX

Answer: We are happy to start work with you on your project as quickly as possible. Our responsiveness and speed to get onto the site make us one of the premier concrete scanning and testing firms around. To learn more about how we can help you with your project, it is best if you contact us directly.