Hydro Excavation Services

Hydro Excavation Services By Safe2core

Potholing & Daylighting for Safe, Non-Destructive Utility Exposure

Safe2core delivers non-destructive hydro excavation services designed to meet the exacting demands of today’s engineering, construction, and subsurface utility engineering (SUE) projects. Combining high-pressure water and vacuum systems, hydro excavation eliminates the risks of traditional mechanical digging — no torn cables, no ruptured pipelines, no unnecessary delays. Through targeted applications such as potholing and daylighting, crews can expose utilities with unmatched precision, reducing project liability and streamlining coordination across job sites.

Safe2core’s hydro excavation teams operate across Sacramento, the Central Valley, and surrounding regions — supporting both public and private sector developments with accuracy, safety, and efficiency as standard. Why trust guesswork when you can see exactly what lies beneath?

Safe2core was recently featured in the news for our commitment to safer utility exposure through advanced hydro excavation in the Sacramento region. [Read the full announcement here]

Precision Excavation with Water and Vacuum: How Hydro Excavation Works

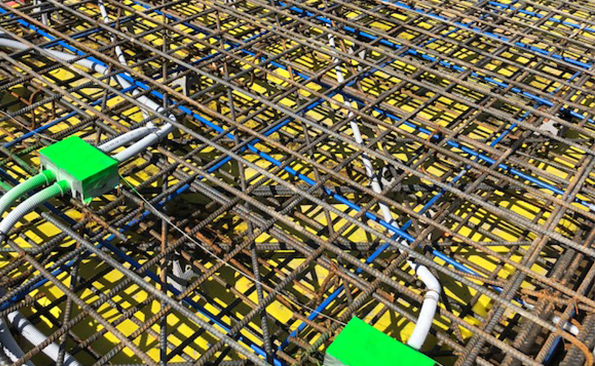

Hydro excavation uses a targeted stream of high-pressure water to displace soil, while a powerful vacuum system simultaneously removes the slurry for offsite disposal. This dual-action technique replaces the need for traditional digging machinery, delivering pinpoint accuracy without mechanical impact to the surrounding area.

Mechanical methods like backhoes or hand digging often lead to accidental strikes on subsurface infrastructure. In contrast, hydro excavation eliminates this risk. The water softens the soil without harming underlying assets, and the vacuum exposes the utilities without direct contact. This non-destructive process significantly reduces incidents involving gas mains, electrical conduit, fiber optics, water systems, sewer lines, and telecommunications cables.

In urban or utility-dense environments, clear and accurate exposure becomes critical. Hydro excavation provides that clarity. Crews can daylight utilities with exacting precision, even in crowded corridors where multiple lines run inches apart. The result? Utility locates that are clean, defined, and safe to work around.

By removing the mechanical element from the excavation process, hydro excavation delivers the safest method currently available for uncovering subsurface assets. This technique allows utility engineers, pipeline specialists, and construction teams to inspect, verify, and map underground infrastructure without risking service disruptions or injury.

Looking at an active project site or developing pre-engineering surveys? This method offers the visibility needed to move forward with confidence and accuracy.

Hydro Excavation Services in Sacramento & Northern California

Safe2core provides precision vacuum excavation and utility daylighting services throughout the Sacramento Valley and surrounding regions. Our local teams are equipped to handle complex utility-dense environments in:

-

Core Cities: Sacramento, West Sacramento, Rancho Cordova, Citrus Heights, Folsom, Elk Grove.

-

North & East Bay: Roseville, Rocklin, Lincoln, Antelope, North Highlands.

-

Suburban Hubs: Carmichael, Fair Oaks, Orangevale, Natomas.

-

Greater Region: Davis, Woodland, Yolo County, Placer County, and El Dorado County.

Precision with Purpose: Potholing & Daylighting in Hydro Excavation

Defining the Objectives of Potholing and Daylighting

Defining the Objectives of Potholing and Daylighting

Potholing refers to the process of excavating small, strategic test holes to visually confirm the exact location of underground utilities. It involves minimal soil displacement and provides focused exposure for utility verification without disrupting the surrounding infrastructure.

By contrast, daylighting extends the excavation to fully expose longer sections of subsurface utilities. This method uncovers the infrastructure from above, offering full visibility to assess the physical condition and geometric placement of pipes, cables, and conduits over broader spans.

Precision Data Gathering for Utility Mapping

Hydro excavation delivers unmatched accuracy in determining the following utility attributes:

- Exact Depth and Horizontal Position: Vacuum excavation pinpoints the three-dimensional coordinates of buried infrastructure, enabling precise CAD-based utility mapping and field mark-outs.

- Material and Size Identification: Full exposure allows visual and tactile inspection of the utility’s construction—whether it’s PVC, steel, copper, or concrete—and its exact diameter or width.

- Orientation, Alignment, and Spatial Conflicts: Contractors can assess the directional flow, bends, and adjacency of utilities. This helps in identifying intersecting or conflicting alignments early in the design process.

Supporting Level A SUE and Field Engineering Accuracy

Potholing and daylighting both contribute directly to Subsurface Utility Engineering (SUE) Level A data—defined as the highest level of utility accuracy. By visually verifying underground infrastructure through non-destructive means, engineers avoid error-prone assumptions made with surface geophysics or historical record mapping alone.

This detailed exposure forms the foundation for accurate engineering designs and construction planning. It eliminates misidentification risks, reduces the chance of utility strikes, and shortens delays related to relocation or redesigns during project execution. As a result, project teams move forward with clarity and confidence.

Q: Why Choose Hydro Excavation Over Mechanical Digging?

A: Zero-Damage Excavation Minimizes Interruptions

Traditional mechanical digging equipment—like backhoes and trenchers—poses a high risk of striking underground utilities. A single utility conflict can result in service disruptions, project delays, or even penalty fines. Hydro excavation eliminates that risk by using pressurized water and a vacuum system, delivering a non-destructive method that exposes utilities without contact. No blades, no collisions—just methodical soil removal that leaves infrastructure completely intact.

Q: How Does Hydro Excavation Provide High-Precision Location and Depth Information?

A: Hydro excavation delivers far greater accuracy than mechanical digging by using pressurized water and vacuum extraction to uncover utilities without disturbing their placement. This non-destructive method reveals the exact depth and horizontal position of buried lines, giving engineering teams sharper and more reliable data for trenchless repairs, new installations, and utility mapping. Because hydro excavation creates cleaner exposure areas, crews can capture high-resolution documentation and maintain easier equipment access during inspections.

Q: Why Is Hydro Excavation Safer in Dense Utility Corridors?

A: Hydro excavation is the safest method for working in areas packed with fiber optics, telecom lines, and other shallow-buried utilities that can be easily damaged by mechanical equipment. By controlling water pressure and removing soil with precision, technicians can expose only the specific layers needed without disturbing fragile assets. This targeted approach allows crews to operate confidently in densely populated utility corridors while minimizing the risk of strikes, service outages, or costly repairs.

Q: How Does Hydro Excavation Perform in Different Soil Conditions?

A: Hydro excavation works effectively across all soil types—including compacted clay, rocky backfill, and loose sand—because it relies on controlled water pressure rather than mechanical force. Water loosens the soil while the vacuum removes it cleanly, producing consistent, precise results regardless of ground composition. This approach creates narrowly defined potholes that reduce restoration time and improve jobsite safety.

Key advantages include:

-

Accurate locating: Utilities are exposed with minimal disturbance.

-

Reduced restoration costs: Smaller, cleaner potholes require less backfilling and repaving.

-

Lower liability risk: No metal tools or mechanical force make contact with buried utilities.

-

Cleaner excavation zones: Less displaced soil and minimal surface disruption.

What Hydro Excavation Services Deliver

| Service Feature | Application | Why It Matters |

|---|---|---|

| Non-destructive digging | Expose utilities safely | Eliminates risk of utility strikes |

| Precise depth & location mapping | Engineering & SUE projects | Sharper data for design & planning |

| Works in all soil types | Clay, sand, backfill, mixed soils | Consistent results without mechanical force |

| Narrow, clean excavation zones | Urban & congested utility corridors | Reduced restoration costs and safer job sites |

Precision-Driven Hydro Excavation Capabilities

Leveraging advanced vacuum and high-pressure water technology, our hydro excavation services deliver accurate, controlled, and damage-free results across a wide spectrum of project requirements. Whether uncovering a single buried utility or managing excavation on industrial-scale sites, our teams adapt to the scope and environmental demands of the job.

Single Potholes and Full-Site Daylighting

Accessing underground utilities without disruption starts with precise potholing and daylighting. Our crews expose single utility points safely for verification, troubleshooting, or integration into new builds. For projects that span entire blocks or facilities, we scale up to carry out full-site daylighting efficiently—mapping utilities down to exact depth and orientation.

Production Potholing for Large-Scale Utility Projects

In renewable energy developments and industrial zones, timelines are tight, and excavation logistics demand consistency. Our production potholing capabilities keep utility exposure moving at pace with construction, supporting underground mapping efforts for wind farms, solar arrays, substations, and grid expansions.

Slot Trenching for Utility Conduit and Sampling

Slot trenching creates narrow, uniform trenches ideal for installing fiber optic lines, electrical conduit, or sampling tubes. Unlike backhoes or trenchers, hydro excavation minimizes disturbance and bypasses obstructions. This technique plays a critical role in environmental testing workflows, especially in geotechnically sensitive zones.

Utility Conflict Identification for Engineering and Design

Before a design moves from CAD to construction, buried utility conflicts must be identified and resolved. Our non-destructive hydro excavation exposes infrastructure with survey-grade reliability, enabling engineers to confirm elevations and locations before finalizing plans. Designers use this verified data to prevent costly mid-project adjustments.

Environmental and Geotechnical Investigations

Site investigation teams rely on excavation support during soil profiling, monitoring well installations, and boring operations. We provide clean, precise access to subsurface layers across varying soil conditions. Whether installing piezometers or preparing access for auger drill rigs, our vacuum excavation methods reduce surface damage and cross-contamination risks.