Vacuum Excavation And Air Excavation Services

Vacuum Excavation Air Excavation for Utilities and Infrastructure

Vacuum excavation is transforming how we approach digging and debris removal. This method is non-destructive and precise.

It uses air or water to loosen soil, which is then vacuumed away. This technique is safer than traditional methods.

It reduces the risk of damaging underground utilities. This is crucial in urban areas with dense infrastructure.

Air excavation and hydro excavation are two main types. Air uses compressed air, while hydro uses high-pressure water.

Both methods offer unique benefits. They are ideal for utility location and trenching.

Vacuum excavation is efficient and environmentally friendly. It minimizes soil disturbance and preserves natural habitats.

This method is gaining popularity in construction and utility sectors. It offers safety, efficiency, and cost-effectiveness.

As technology evolves, vacuum excavation continues to improve. It plays a vital role in modern infrastructure development.

What is Vacuum Excavation?

Vacuum excavation is a modern, non-destructive digging technique. It uses a unique method to remove soil without harm to underground utilities.

The process involves using air or water to dislodge soil particles. This soil is then vacuumed into a holding tank for disposal or reuse.

This method is incredibly precise, making it valuable for delicate projects. It reduces the chance of hitting and damaging vital underground lines.

There are two main types of vacuum excavation:

- Air Excavation: Uses compressed air to loosen soil.

- Hydro Excavation: Employs high-pressure water to break up the ground.

By using these methods, operators can create precise holes or trenches. This precision is essential in urban environments with complex infrastructure.

Vacuum excavation is not only efficient but also environmentally friendly. It disturbs less soil and conserves resources, benefiting both the project and the planet.

Question- How Vacuum Excavation Works: The Process Explained

A: Vacuum excavation combines technology and precision to achieve remarkable results. The process relies on specialized machinery designed for versatility and safety.

First, a crew identifies the excavation site. They analyze the area for existing utilities and map out the digging plan.

Next, the machinery uses either air or water to loosen the soil. This is done with minimal disturbance to the surrounding environment.

The loosened soil is then vacuumed into a large storage tank. This step ensures a clean site with minimal leftover debris.

Key steps in the vacuum excavation process include:

- Site Assessment: Determine utility locations and define the work area.

- Soil Loosening: Use air or water to dislodge the ground.

- Vacuum Collection: Suck up the loose soil into a holding tank.

- Site Review: Inspect the excavation area for safety and completeness.

This method is significantly safer compared to traditional digging. It reduces risks of damaging underground infrastructure.

Moreover, vacuum excavation effectively addresses challenges posed by different soil types. It works well in rocky or heavily compacted areas, where other methods might struggle.

The process is efficient, often completing in less time than traditional excavation. This speed, coupled with precision, makes it an ideal choice for many projects.

Question: Air Excavation vs. Hydro Excavation: Key Differences

Answer: Vacuum excavation splits into two main techniques: air and hydro excavation. Each method has unique features and uses.

Air excavation uses compressed air to break up the soil. This air jet is gentle yet effective in displacing dirt.

In contrast, hydro excavation employs high-pressure water for soil movement. This water jet is more forceful, cutting through denser materials.

Both methods involve vacuuming the displaced material for removal. This maintains a tidy work area with minimal environmental impact.

Here are key differences between the two:

- Air Excavation:

- Uses compressed air

- Ideal for delicate work

- Gentle on roots and utilities

- Hydro Excavation:

- Uses high-pressure water

- Effective in dense soils

- Quickly penetrates tough surfaces

by America’s Outdoor Adventure Park (https://unsplash.com/@aoapark)

Air excavation excels in environments where preserving roots or delicate utilities is crucial. Its gentle approach makes it suitable for softer soils and archaeological digs.

Meanwhile, hydro excavation is the preferred choice in tougher conditions. It rapidly clears heavily compacted earth and dense clay, saving time on difficult terrains.

Choosing between these methods depends on project needs. Ground conditions and precision demands play a central role in the decision.

Both air and hydro techniques offer non-destructive digging. They ensure underground structures remain untouched and safe throughout the process.

In summary, selecting the right method enhances efficiency and outcomes for excavation projects. Understanding each one’s strengths helps in making informed choices for site requirements

Question: Benefits of Vacuum Excavation for Utilities and Infrastructure

Answer: Vacuum excavation offers numerous advantages for utilities and infrastructure projects. Its non-destructive nature is a major benefit.

Precision is a hallmark of vacuum excavation. It minimizes the risk of damaging underground utilities while digging. This reduces costly repair and delays.

Another key benefit is the safety it ensures for workers and the public. The method involves minimal manual labor, decreasing accident risks.

The environmental footprint of vacuum excavation is small. It reduces soil disturbance and preserves surrounding flora and fauna.

Here are some core advantages of vacuum excavation:

- Precision:

- Minimal utility strikes

- Accurate soil removal

- Safety:

- Reduced manual labor

- Lower accident risk

by okeykat (https://unsplash.com/@okeykat)

Cost efficiency is another boon. Avoiding damage leads to fewer repairs, lowering overall project expenses over time.

Speed and efficiency are also compelling reasons to choose vacuum excavation. The process is faster than traditional methods, which rely on heavy equipment.

Versatility is a significant plus. Vacuum excavation works across various soil conditions and project sizes, enhancing flexibility for diverse applications.

In urban environments, where infrastructure is dense, the method really shines. Its ability to navigate confined spaces without disturbance is invaluable.

Finally, vacuum excavation aligns with sustainable practices. It promotes cleaner operations, supporting goals for environmentally friendly construction projects.

These benefits make vacuum excavation an ideal choice for modern utilities and infrastructure development. The method’s precision, safety, and environmental advantages are undeniably beneficial.

By adopting vacuum excavation, professionals can ensure efficient and effective project execution. The method’s positive impacts on infrastructure tasks are far-reaching and substantial

Question: Safety Advantages: Protecting Workers and Underground Assets

A: Vacuum excavation is a revolutionary method with significant safety advantages. Ensuring the well-being of workers and protecting underground assets are its top priorities.

The process eliminates the need for manual digging. This minimizes exposure to potential hazards, reducing the risk of personal injury on-site.

A key safety feature is the precision it offers when operating near utilities. This significantly lowers the chances of accidental utility strikes, which can be dangerous and costly.

The method supports a less noisy environment, limiting noise pollution. This creates a safer and more comfortable atmosphere for workers and nearby communities.

Here’s a quick look at safety advantages:

- Worker Safety:

- Less manual labor

- Reduced injury risk

- Asset Protection:

- Precision near utilities

- Minimized utility strikes

by Darrel Louise Almanzor (https://unsplash.com/@darrel23)

The equipment used in vacuum excavation typically meets high safety standards. Built-in safety features, such as emergency shut-offs, further safeguard operation.

Proper training and adherence to guidelines ensure that teams are well-prepared. This enhances both safety and efficiency, reducing potential risks on-site.

By prioritizing safety, vacuum excavation not only protects lives but also maintains infrastructure integrity. These advantages make it an ideal choice for numerous applications

Environmental Impact and Sustainability

Vacuum excavation is a lower-impact alternative to mechanical digging because it minimizes surface disruption and limits unnecessary soil displacement. By loosening soil with air or controlled water pressure and removing it by vacuum, projects can preserve surrounding environments while maintaining excavation accuracy.

- Reduced soil disturbance that helps protect ecosystems and sensitive areas

- Lower waste generation through targeted excavation and cleaner spoil handling

- Reduced erosion and sedimentation due to smaller excavation footprints

For projects with environmental constraints or strict restoration requirements, vacuum excavation supports sustainable construction practices without sacrificing safety or efficiency.

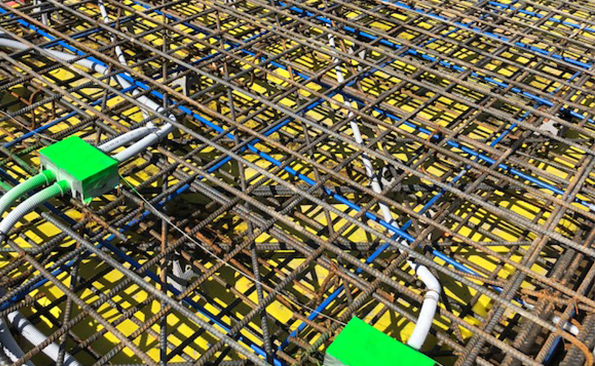

Applications of Vacuum Excavation in Utilities and Infrastructure

Vacuum excavation is widely used in utility and infrastructure projects where precision and safety are critical. It is particularly effective in congested corridors and high-risk environments where traditional excavation methods increase the likelihood of damage.

- Utility locating and verification through potholing and daylighting

- Trenching and slot trenching in dense urban environments

- Infrastructure maintenance including pipeline access and stormwater systems

- Fiber optic and conduit installation support

- Selective debris removal in confined or sensitive work zones

- Archaeological and environmentally sensitive excavation

- Tree root protection near protected landscaping

- Hazardous material handling support with reduced exposure risk

Debris Removal and Site Cleanliness

Vacuum excavation improves jobsite cleanliness by removing spoil material directly into a debris tank. This keeps work areas organized, reduces trip hazards, and improves overall site safety—especially in urban or active project environments.

- Rapid removal of excavated material

- Cleaner, more controlled excavation zones

- Reduced clutter and improved site access

Vacuum Excavation vs. Traditional Digging Methods

Traditional mechanical excavation methods rely on force and heavy equipment, increasing the risk of utility strikes and unnecessary surface disruption. Vacuum excavation offers a controlled alternative that improves safety and accuracy.

- Precision: Targeted excavation without disturbing surrounding utilities

- Safety: Lower risk of damaging gas, electric, fiber, water, and sewer lines

- Environmental impact: Reduced soil disturbance and restoration scope

- Cost control: Fewer repairs, outages, and schedule delays

Choosing the Right Method: Air vs. Hydro Excavation

Selecting air or hydro excavation depends on soil conditions, site constraints, and operational requirements.

- Hydro excavation: Effective in dense soils and clay; ideal when controlled water use is feasible

- Air excavation: Preferred in sandy or loose soils or where water use is restricted

Evaluating utility density, drainage conditions, and environmental constraints helps determine the most effective approach for each project.

Equipment and Technology Overview

Vacuum excavation relies on specialized equipment designed for precision and efficiency, including vacuum trucks, air compressors, high-pressure water systems, and debris containment tanks. These systems allow operators to adapt to varying soil conditions while maintaining controlled excavation zones.

Cost Considerations and Long-Term Value

While vacuum excavation may involve higher upfront costs than traditional digging, it often reduces total project cost through avoided utility strikes, reduced restoration work, and improved project timelines.

- Lower repair and outage-related expenses

- Reduced downtime and schedule disruptions

- Improved risk management and project certainty

Best Practices and Safety Guidelines

Safe and effective vacuum excavation depends on proper planning, trained operators, and disciplined execution.

- Comprehensive site assessment and utility marking

- Routine equipment inspections and maintenance

- Operator training and adherence to safety protocols

- Use of appropriate personal protective equipment

- Clear documentation and verification of exposed utilities

Future Trends in Vacuum Excavation

Advances in automation, data integration, and environmentally efficient equipment continue to expand the capabilities of vacuum excavation. These developments support greater accuracy, reduced environmental impact, and improved decision-making in complex infrastructure projects.

Conclusion: Vacuum Excavation in Modern Infrastructure

Vacuum excavation plays a critical role in modern infrastructure development by providing a safe, precise, and non-destructive method for exposing underground assets. As utility networks grow more complex and sustainability expectations increase, vacuum excavation remains a preferred solution for minimizing risk while maintaining project efficiency and environmental responsibility.