Summary: Ground Penetrating Radar (GPR) is a non-destructive technology used in construction to detect subsurface hazards, locate utilities, and assess structural elements without digging or coring. By emitting high-frequency radar pulses into concrete or soil, GPR identifies materials like rebar, post-tension cables, voids, and electrical conduits in real time. This improves safety, reduces risk, and ensures compliance with OSHA excavation standards. GPR scanning is essential before cutting, drilling, or excavating. It helps prevent accidents, utility strikes, and structural damage by accurately mapping hidden features. The technology also supports predictive maintenance and integrates with BIM tools for smarter planning. From utility mapping to slab analysis, GPR enhances job site efficiency and protects workers from costly or dangerous surprises.

Ground Penetrating Radar (GPR) transforms the way construction teams investigate subsurface conditions. By emitting high-frequency radar pulses into the ground or concrete, this non-destructive technology detects changes in material properties, enabling accurate imaging of objects, voids, and utility lines beneath the surface.

A standard GPR system consists of four core components: an antenna that sends and receives radar signals, a control unit for data processing and system management, a power supply, and a display device to visualize the scanned data in real time. Together, these parts allow users to see hidden elements without digging or coring.

In construction, GPR plays a central role in locating rebar, post-tension cables, conduits, and voids within concrete slabs. It also supports utility mapping, structural assessments, and pavement layer analysis—critical for both new builds and renovations. Compared to traditional excavation, GPR offers faster results, higher accuracy, and zero destruction to the scanned area, which minimizes risk, reduces costs, and improves worker safety.

Subsurface Hazard Identification: Spotting Dangers Before They Escalate

Detecting Voids, Sinkholes, and Unstable Ground Beneath Construction Sites

Unseen ground conditions can halt construction fast. Ground Penetrating Radar (GPR) excels at identifying subsurface anomalies—such as voids, sinkholes, and pockets of unstable soil—before they endanger workers and equipment. By sending high-frequency electromagnetic waves into the ground and analyzing the patterns of how they reflect back, GPR systems reveal changes in dielectric properties that correlate with subsurface disruptions.

In karst terrain, for instance, GPR can map the extent of subsurface cavities formed by the dissolution of limestone or dolomite. These voids may not be visible from the surface but pose serious collapse risks once heavy equipment starts to operate overhead. Multichannel GPR arrays, mounted on carts or vehicles, can scan large areas quickly, generating 3D subsurface models that visualize these hazards in real time.

-

Voids appear as hyperbolic reflections on radargrams, indicating air-filled or unconsolidated spaces.

-

Sinkholes often show as disrupted stratigraphy or anomalies in expected layering patterns, especially when paired with resistivity or seismic data.

-

Unstable soils display inconsistent dielectric responses often coupled with higher attenuation of radar signals.

Preventing Accidents Related to Underground Hazards

Falling equipment costs more than cash—it jeopardizes lives. Identifying fragile subsurface features with GPR helps prevent trench collapses, sudden ground settlements, and heavy machinery failures. Once anomalies are flagged, geotechnical engineers can deploy boreholes or cone penetration tests in targeted locations to confirm material stability and plan excavation or reinforcement strategies accordingly.

In risk-prone zones, GPR surveys prior to foundation work will change the design or postpone digging, not because of guesswork, but because data confirms a hazard. In some cases, predictive maintenance schedules for infrastructure such as bridges or roads have been established based on GPR scans detecting ground movement or void growth over time.

Real-World Example: Highway Expansion Delayed, Catastrophe Averted

During the 2022 widening project of a major interstate in Florida, survey teams deployed GPR to scan a 10-mile segment flagged for soft soil risks. Scans revealed several large anomalies beneath the proposed roadbed, some stretching over 8 meters wide. Follow-up drilling confirmed a previously unmapped sinkhole cluster, formed by slow limestone erosion beneath the surface. Instead of proceeding and risking collapse under heavy traffic, the road design was adjusted, and reinforcement grids were installed before pavement began. The project added two weeks to planning, but likely saved the state millions—and lives—by avoiding structural failures post-completion.

Utility Detection and Mapping: Avoid Costly Strikes

Pinpointing Underground Utilities with Accuracy

Before the first shovel hits the ground, ground penetrating radar (GPR) identifies what lies beneath. High-frequency electromagnetic waves emitted by GPR systems bounce back when they encounter different materials underground. Differences in signal reflection reveal the location and depth of buried infrastructure such as gas lines, electrical conduits, telecommunications cables, and water mains.

Detection depth and resolution depend on soil composition, moisture content, and antenna frequency. For instance, a 400 MHz antenna can detect utilities up to approximately 3 meters deep in dry sandy soil with a horizontal resolution of 0.1 to 0.2 meters.

Reducing Utility Strikes: Avoid Injuries, Fines, and Downtime

Utility strikes carry more than just repair costs — they invite penalties, injure workers, and halt job site operations. According to the Common Ground Alliance (CGA), over 192,000 utility damages were reported across the U.S. in 2022 alone. Excavation work that proceeds without reliable underground mapping makes such incidents increasingly likely.

When workers strike a pressurized gas main or high-voltage electrical cable, the resulting hazards can escalate in seconds. GPR minimizes this risk by identifying infrastructure invisibly buried under pavements, fields, or concrete slabs. By integrating GPR insights at the planning stage, teams reduce exposure to emergency repairs and OSHA violations.

Mapping Utilities Before Excavation: Procedures That Work

Systematic mapping of underground assets transforms ambiguous subsurface data into actionable field plans. Here’s how effective teams prepare:

-

Grid scanning: Technicians divide areas into systematic grids to perform overlapping GPR sweeps, ensuring no sections are missed.

-

Geo-referenced data capture: By pairing results with GNSS receivers, users generate precise coordinates for detected utilities.

-

Layer classification: Different readings get assigned to utilities based on depth, signal strength, and known material properties—gas, water, electric.

3D visualization also enhances the interpretation process. Some scan outputs integrate with CAD or GIS software, allowing crews to plot infrastructure data over site models for immediate reference during trenching or drilling.

Working with Utility Records and Coordination Teams

Ground scanning data becomes exponentially more useful when cross-referenced with as-built drawings and city records. However, these documents often contain discrepancies due to undocumented repairs or aging infrastructure. GPR helps to verify, supplement, or correct outdated utility maps.

Coordinate with local utility companies through systems like 811 “Call Before You Dig.” These alerts flag known infrastructure, helping prioritize zones for focused GPR investigation. When survey teams share scan outputs back to utility providers, future work in the area proceeds with higher confidence and lower risk.

Concrete Scanning Best Practices

Pinpointing Embedded Objects Before the Cut

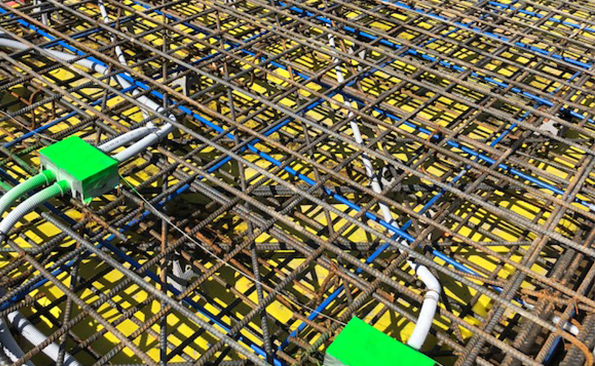

Before any coring, cutting, or drilling through concrete structures begins, identifying the placement of embedded objects—such as rebar, post-tension cables, and electrical conduits—is not negotiable. Ground Penetrating Radar (GPR) offers real-time imaging of subsurface anomalies that could compromise the project’s integrity or worker safety if struck.

Operators scan slabs, walls, and columns to view the depth and spacing of reinforcement bars. In post-tensioned structures, GPR pinpoints the exact location of cables, which carry high tension and can snap violently if damaged. The same applies to conduit pathways, which may carry high voltage or sensitive communication lines. Locating these components before any surface disruption will eliminate guesswork and prevent irreversible errors.

Guaranteeing Structural Safety During Intrusive Work

Every change made to a concrete structure introduces a variable. Cutting into a reinforced slab without knowing the internal layout can weaken the structural load path. GPR scanning mitigates this risk by delivering precise subsurface profiles, which engineers use to determine safe entry points for concrete intrusion.

When GPR is used to verify reinforcement patterns, structural engineers can assess load distribution more accurately. This allows teams to preserve load-bearing designs while still achieving the necessary modifications. Cutting through a tension zone or a cable duct without this scan-backed data will compromise safety and violate engineering codes.

Preventing On-Site Injuries and Utility Damage

Concrete scanning doesn’t just protect buildings—it protects workers. A misaligned core drill can shear through live conduits or sever a pressurized water line. GPR scans eliminate blind spots, sharply reducing incidents of electrocution, flooding, or exposure to hazardous materials concealed within concrete.

-

Workers remain out of harm’s way when cable routes are traced and marked before drilling.

-

Downtime caused by emergency repairs to energized systems drops to near zero when scans dictate the layout.

-

Repair costs from accidental strikes become avoidable line items on a project ledger.

Strategic Timing: When to Scan, Where to Scan

Not every stage in a construction project demands the same scanning intensity. Determine scanning schedules based on planned activities and the known complexity of the slab composition:

-

Pre-corings and core-drilling: Scan targeted areas to plan boreholes safe from reinforcement and utilities.

-

During layout planning: Identify conflicting elements early before structural or MEP installations begin.

-

Post-installation audits: Verify reinforcement installations, ensuring adherence to structural plans.

Structural columns, elevator shafts, slab edges, and equipment mounting zones typically demand deeper scans due to increased reinforcement density or utility proximity. Don’t assume uniformity—every zone requires its own analysis. Adjust scanning depth based on slab thickness, known layering, and expected conduit positions.

Interested in improving safety outcomes and reducing rework hours? Start by rethinking when concrete scanning happens on your site schedule. Then adjust your protocols accordingly.

Structural Integrity Assessments: Beyond Surface-Level Insights

Evaluating Thickness and Condition of Structural Elements

Ground Penetrating Radar (GPR) provides high-resolution imaging of internal concrete structures, enabling precise evaluation of slab thickness, material homogeneity, and embedded features. Engineers use GPR to measure layer depth variations in real time without destructive coring. For example, GPR can identify a 15 cm reinforced concrete slab’s actual thickness within ±0.5 cm accuracy, depending on the material makeup and scan frequency. This level of precision supports quality control during both new construction and retrofitting tasks.

Detecting Early Signs of Structural Degradation

By analyzing waveform anomalies and attenuation patterns, GPR locates hidden structural weaknesses before they escalate. Cracks, delamination, and voids—often invisible on the surface—cause disruptions in radar signal reflections. These variations produce identifiable signatures that trained analysts translate into actionable insights. Detecting a shallow void beneath a concrete parking deck, for instance, can prompt immediate intervention, preventing progressive failure. Moisture ingress, which indicates corrosion potential in embedded rebar, also shows up as signal amplitude drops or phase shifts in the radargram.

Strategic Maintenance and Safety Planning

Structural evaluations with GPR contribute directly to predictive maintenance strategies. Routine scanning identifies deterioration trends, allowing asset managers to track change over time and assign repair priorities based on risk profiles. Large facilities such as hospitals or stadiums rely on this capability to extend infrastructure lifespan without wide-scale shutdowns.

-

Schedule-targeted repairs based on degradation patterns.

-

Allocate budgets more efficiently using real data, not assumptions.

-

Align maintenance cycles with actual structural conditions, not arbitrary timelines.

Consider the impact on lifecycle costs: a GPR-driven maintenance protocol can reduce emergency structural repairs by up to 30%, according to civil engineering reports by the U.S. Federal Highway Administration. This approach transforms asset management from reactive to proactive while preserving the integrity and safety of the built environment.

Interpreting GPR Data: Turning Scans into Actionable Decisions

Reading GPR Radargrams: Making Sense of Subsurface Echoes

At the core of Ground Penetrating Radar (GPR) interpretation lies the radargram—a grayscale record of reflected signals captured by the antenna as it travels across a surface. High-reflectivity contrasts, such as metallic pipes or reinforced steel, appear as hyperbolic shapes, while uniform materials like soil layers generate horizontal bands. Effective interpretation starts with identifying these patterns and correlating them to known material properties and site expectations.

The vertical scale indicates depth, generally calibrated against signal velocity in the target material. This means the same feature can appear deeper or shallower depending on soil composition, moisture content, or fill type. Analysts must adjust velocity values—often via calibration cores—to translate two-way travel time into accurate depth readings. Without proper calibration, depth estimates can deviate by over 30%.

Training vs. Outsourcing: Who Should Read the Data?

On-site teams benefit from basic GPR literacy for immediate decision-making during scanning. However, full interpretation often demands expertise in subsurface geophysics, data filters, and material science. Trained specialists apply gain adjustments, depth slicing, migration techniques, and filtering modes—such as background subtraction or Hilbert Transformations—to refine clarity and extract more detail from raw scans.

-

In-house capability works well when recurring scans are part of the workflow and staff can be certified to Level I or II standards based on ASTM D6432 specifications.

-

Third-party consultants bring high interpretive precision, especially for complex environments such as multi-layered urban sites with congested subsurface networks.

Deciding between these paths depends on project lifecycle frequency, internal expertise availability, and the risk level associated with misinterpreted data.

From Data to Decisions: Embedding Results into Project Plans

Raw data becomes impactful only when woven into real-time planning and risk mitigation workflows. Mapping software like AutoCAD Civil 3D, Trimble Business Center, or Bentley Subsurface Utility Engineering modules allow seamless integration of geolocated scan data into broader site plans. Color-coded depth contours, object type annotations, and post-processed 3D visualizations feed directly into excavation strategies and rerouting decisions.

Teams embed GPR results into pre-dig clearance procedures, trench shield placement, and crane pad preparations. This reduces unexpected rework and aligns with safe-dig protocols enforced by construction authorities. Decision trees based on radargram data help determine go/no-go scenarios at critical phases, such as prior to auger operations or concrete coring.

Common Missteps in GPR Interpretation—and How to Avoid Them

-

Ignoring material velocity corrections: This skews depth estimations, especially in heterogeneous soils where velocity can range between 0.06 to 0.15 meters/ns.

-

Mistaking hyperbolas for pipes without confirmation: Not all hyperbolic returns signify utilities—rocks, cracks, and voids produce similar echoes. Reliable identification comes from pattern cross-verification and multiple orientation passes.

-

Over-filtering raw data: While filters clean clutter, excessive smoothing erases weak but critical reflections. Operators should apply minimal filtering on initial passes and revisit raw images for confirmation.

-

Viewing radargrams as static snapshots: GPR data is inherently three-dimensional. Instead of relying on a single pass, continuous profile analysis and time-slice interpretations capture fuller context.

Skilled interpretation amplifies the value of GPR investments. Properly read scans lead to decisiveness on-site—early risk detection, confident excavation, and robust structural planning all flow from this data-literate approach.

Meeting Safety Compliance with Ground Penetrating Radar: Standards That Shape the Jobsite

Aligning with OSHA and Local Ground Assessment Rules

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) require strict adherence to subsurface investigation protocols before any excavation begins. Under OSHA Standard 1926.651, employers must determine the location of underground installations—including sewer, telephone, fuel, electric, and water lines—prior to digging. Ground Penetrating Radar (GPR) directly supports this requirement by identifying and mapping in-ground utilities without disturbing the surface.

Local jurisdictions often enforce additional safety codes built on top of federal guidelines, especially in urban areas where underground infrastructure is dense. GPR scanning offers a non-invasive solution that reduces reliance on outdated as-built drawings or assumptions, aligning projects more consistently with both federal and municipal safety laws.

Achieving Compliance During Drilling and Excavation

Excavation violations are among the top cited safety infractions in construction. GPR mitigates this risk by spotting hidden electrical conduits, gas lines, post-tension cables, and other hazards in real-time. Compliance with 811 “Call Before You Dig” laws doesn’t stop at making the call—accurate verification of utility paths before starting work delivers tangible legal protection.

In projects involving core drilling or saw cutting, especially in post-tensioned slabs or slab-on-grade systems, GPR scanning ensures separation from load-bearing elements and embedded services. This satisfies safety protocols and meets client and insurer mandates for non-destructive evaluation.

Supporting Documentation and Reporting Requirements

Proper documentation turns GPR into more than a detection tool—it becomes a compliance asset. Scanning records serve multiple operational functions:

-

Proof of Due Diligence: Digital records and annotated scan maps demonstrate proactive risk management during audits or incident investigations.

-

Worksite Logs: Many contractors use GPR data to substantiate daily field reports and update safety checklists.

-

Permitting Support: Municipal permitting often requires evidence of utility location before trenching; GPR visuals satisfy that requirement efficiently.

Several GPR systems integrate with GIS and CAD platforms to streamline the transfer of scan data into official project records. When inspectors or regulators review subsurface plans, scan outputs offer verifiable spatial evidence.

Reducing Liability and Supporting Insurance Protocols

Insurance providers assessing construction risk increasingly expect builders to adopt preventive technologies. Using GPR directly impacts underwriting decisions by lowering the probability of underground strikes. Some insurers even adjust premiums based on scanning policies reported during preconstruction planning.

In the event of property damage or utility rupture, project teams with documented GPR scans avoid being held liable for negligence. Contractors can demonstrate reasonable steps were taken to identify and avoid buried systems, which often reduces exposure during claims evaluation or litigation.

Minimizing Construction Delays Through Better Planning

Using GPR to Eliminate Surprises Before They Cost You Time

Construction delays often stem from one source: the unexpected. Early-stage scanning with Ground Penetrating Radar (GPR) identifies hidden subsurface features—like utilities, voids, or uncharted obstructions—before excavation begins. When deployed during pre-construction surveys, GPR adds crucial detail to site knowledge, flagging anomalies that could halt operations midstream.

Consider this: a utility strike can shut down a site for hours, sometimes days. The Common Ground Alliance reported over 213,000 excavation-related damages in the U.S. in 2021 alone. Most of those incidents were preventable. When GPR scanning becomes part of early planning, crews work against known factors rather than assumptions.

Syncing Scans With Project Scheduling Milestones

Integrate GPR results directly into your project timeline and attach scanning to milestone reviews. For example:

-

Site Mobilization: Schedule GPR in parallel with initial topographic surveys to deliver subsurface data before excavation equipment arrives.

-

Foundation Work: Use GPR to guarantee clear zones for drilling and footing placement, especially in retrofit or brownfield sites.

-

Pre-installation Phases: Scan slab areas to verify rebar and conduit locations before core drilling or saw cutting.

Each scan slot aligns with a downstream decision. When subsurface data influences scheduling, risk becomes measurable—and manageable.

Faster Permits, Fewer Redlines

Permit applications accelerate when engineering plans include GPR-backed data on utility presence, soil composition, or potential voids. Regulatory agencies respond faster to documentation that reflects a high certainty of site conditions. GPR reports also reduce back-and-forth during plan reviews by resolving subsurface uncertainties upfront.

Real-World Case Studies: Time Saved in the Dirt

-

On a municipal library retrofit in Oakland, CA, GPR scanning identified abandoned utility lines embedded in a 1960s-era foundation. Result: demolition strategy adjusted without surprises, avoiding nearly two weeks of schedule impact.

-

During fiber-optic trenching in Dallas, TX, GPR scanning uncovered undocumented clay drainage channels. By adjusting trench paths early, crews avoided hand-digging delays and finished the install three days ahead of schedule.

-

A Toronto high-rise broke ground with a full GPR subsurface model. Structural engineers avoided drilling into post-tension cables during elevator shaft installation, preserving both timeline and warranty coverage.

Proactive use of GPR shifts project momentum forward from day one. When you scan before you schedule, construction teams eliminate guesswork—and keep progress on track.

Evaluating the Cost-Effectiveness of GPR in Your Project

Pinpointing the Value: Direct and Indirect Savings

Ground Penetrating Radar (GPR) reduces project expenses in ways both obvious and subtle. Direct cost savings come from eliminating expensive rework, avoiding physical damage to underground utilities, and sidestepping regulatory fines. For example, the Common Ground Alliance reported in its 2022 DIRT Report that utility strikes alone cost the U.S. construction industry over $30 billion annually in delays, repairs, and service disruptions.

Indirect savings accumulate over the life of the project. Preventing one serious on-site injury—averaging $42,000 in direct costs and $33,000 in indirect costs according to the National Safety Council—justifies the investment in GPR technology. There’s also reduced liability exposure, lower insurance premiums, and fewer workers’ compensation claims when subsurface hazards are accurately identified ahead of time.

Measuring Risk: GPR vs. Cost of Inaction

Skipping GPR carries a different kind of cost: project uncertainty. Hitting unknown objects during excavation can lead to shutdowns, design changes, or injury investigations. Redesigning foundations around unmarked utilities or structural impediments can extend timelines by weeks and inflate costs significantly. In one national case study, a GPR investment of $8,000 for a hospital expansion project prevented a utility strike that would have incurred $120,000 in repairs and five weeks of delay.

Ask these questions before deciding against scanning:

-

What would a buried conduit strike cost per day in project delays?

-

How would emergency rerouting affect the construction schedule or project scope?

-

Can the budget absorb an insurance claim or OSHA investigation tied to an avoidable incident?

Budget Integration: GPR in the Planning Phase

Allocating funds for GPR early in project development shifts subsurface risk from “unforeseen contingency” to “manageable variable.” During preconstruction planning, GPR providers can be engaged alongside surveying and geotechnical teams. This enables informed routing of utilities, optimized excavation plans, and smoother permit acquisition. Building in GPR services during schematic design or design development phases ensures pricing accuracy and improves contractor confidence during bidding.

-

Include GPR in the line item breakdown of soft costs.

-

Bundle GPR with geotechnical surveys or Phase I environmental assessments.

-

Coordinate with civil engineers and MEP consultants to align scanning scope with utility mapping needs.

ROI That Extends Beyond Dollars

Return on investment from GPR isn’t just a number on a spreadsheet. It’s seen in accelerated project timelines, more confident decision-making, and fewer delays caused by emergencies or rework. On complex commercial builds, GPR has shown to reduce field change orders by up to 30%, and schedule slippage by 15–20%. When decision-makers trust the data beneath their feet, they build smarter, faster, and with fewer surprises.

Bridging the Gap: Integrating GPR with BIM and Site Planning Tools

Combining GPR Data with Building Information Modeling (BIM)

Seamless integration of Ground Penetrating Radar (GPR) data into Building Information Modeling (BIM) environments gives project teams a clearer picture of the subsurface environment. When GPR datasets are imported into BIM platforms using compatible formats such as IFC or via point cloud integrations, they become spatially and contextually aligned with above-ground architectural models. This digital overlay enables project planners to make informed decisions rooted in actual site conditions, reducing guesswork during excavation or structural modification phases.

Generating 3D Visualizations of Hidden Infrastructure

With 3D visualization, GPR scan outputs transition from raw radargrams to immersive subsurface models. Tools like Trimble RealWorks, Autodesk ReCap, and Bentley’s OpenRoads Designer support the conversion of GPR datasets into 3D models. These models display conduit paths, voids, foundations, and other embedded features in contrast and depth, which allows users to rotate, section, and interrogate the underground data inside the full site model. Incorporating these visuals into digital twins helps monitor asset integrity over time and supports predictive maintenance planning.

Enhancing Real-Time Collaboration Across Teams

By integrating GPR outputs within a centralized BIM environment, coordination between contractors, civil engineers, and site planners becomes more precise. Clash detection doesn’t apply only to mechanical, electrical, and plumbing systems anymore—it extends to below-surface anomalies. On high-stakes infrastructure projects, synchronized updates ensure that when one discipline flags a subsurface concern, others can adjust their models accordingly. This reduces field changes, which historically account for roughly 10-15% of total construction costs according to McKinsey & Company.

Boosting Communication, Documentation, and Auditing

BIM integrations allow GPR data to be time-stamped, version-controlled, and stored within a federated coordination model. During safety audits or regulatory reviews, teams no longer rely solely on printed utility maps or as-builts. Inspectors gain access to comprehensive records that include scanned depths, material composition data, signal anomalies, and anomaly classification. When integrated with site planning software, these models also route fieldwork based on safety-critical insights, lowering the incidence of utility strikes and supporting OSHA compliance workflows.

-

Documentation accuracy: All stakeholders reference the same model, with GPR layers documented to centimeter precision.

-

Communication fluidity: Visual models offer a common language between technical and non-technical team members.

-

Regulatory readiness: Complete and traceable infrastructure records simplify bid submissions and audit trails.

Looking to futureproof your construction workflows? Consider how tightly-coupled GPR and BIM workflows guide safer, smarter planning from below the surface up.

Strengthening Construction Safety with Ground Penetrating Radar

Bringing Safety to the Forefront with GPR

Ground Penetrating Radar (GPR) consistently delivers tangible safety outcomes on active construction sites. By detecting subsurface utilities, voids, rebar, and other hidden anomalies, it eliminates guesswork—transforming hazardous unknowns into controlled variables. Whether identifying post-tension cables in concrete slabs or scanning for old foundations prior to excavation, GPR highlights threats that legacy methods routinely miss.

Several core benefits point to why GPR belongs in every construction safety strategy:

-

Non-destructive testing: Projects proceed without damaging the structure or the ground, reducing the risk of structural compromise.

-

Real-time results: Scans deliver immediate visual feedback, allowing site managers to make quick, accurate calls without halting work.

-

Broad range of applications: From utility mapping to concrete imaging, GPR adapts across phases—from pre-planning through as-built analysis.

-

Reduction in strike incidents: Avoided contact with power lines, water mains, gas lines, or telecom conduits directly correlates to fewer injuries and lower insurance premiums.

Embedding GPR into Your Project from Day One

Integrating GPR into site planning isn’t an optional enhancement—it’s a strategic move toward shortening timelines, preventing injuries, and ensuring regulatory compliance. When included at the project’s outset, GPR shapes decisions about trench paths, permit scope, concrete design, reinforcement detailing, and machinery deployment.

Consider where timing and budget meet risk: delays from a single underground utility strike can average $56,000 in damages, based on Common Ground Alliance’s 2022 DIRT Report. When multiplied by the risk factors across a multi-phase build, the ROI of early GPR scanning becomes evident. Construction managers who systematize its use report not only improved safety but also tighter coordination between trades.

Take a Step Toward Proactive Site Management

How are you currently ensuring visibility beneath the ground or within concrete? Are your teams relying on legacy methods or third-party documentation that may no longer reflect site reality?

Invite a GPR specialist to your planning meeting. Include scanning scopes in preconstruction RFPs. Train supervisors in interpreting radargrams or integrating scan data with digital twin models. By making ground-penetrating radar part of the conversation early, you create a measurable shift—from reactive hazard response to informed prevention.

GPR isn’t just a tool. It’s a workflow—one that aligns every stakeholder with your ultimate objective: a safer, smarter structure built on solid ground.

Content ideas