When it comes to locating unmarked utilities beneath the ground’s surface, knowing the precise location and depth can make the difference between a smooth, successful project and a potentially deadly, fractious pain in the neck. Anyone who’s spent any time at all on a construction site knows the obstructions and utilities which cannot be seen above the ground are only half the problem but could pose significantly more than half the risk. For thousands of years, people have struggled with the questions attached to detecting subsurface buried objects in the earth: how to find them, how they can be identified, and how to record their locations so as to ensure they’re avoided and minimize ancillary damages to the site or injury to workers.

The history of the science of locating buried utilities and objects in the soil is varied, checkered, sometimes amusing, and horrifying in equal parts.

Some methods verge on the bizarre, such as the use of dowsing rods depicted in figure studies and drawings dating back as far as ancient Egypt. These primitive tools are reputed to have functioned as low-frequency antennas of a sort, intended for use in scrying out subsurface reserves of fresh water and buried metal deposits. Others are outrageous to modern sensibilities, with our access to three-dimensional imaging and nondestructive creation of subsurface maps. Modern history is replete with stories of brute-force ground disturbance in search of treasures of antiquity and financial value, such as the heedless plunder and untold destruction of necropolises (cemetery developments) and their contents across the ancient world in the name of archaeology by people of dubious qualification. Some of the best-known “luminaries” of this type are Howard Carter and Lord Carnarvon, the English figures behind the excavation of the tomb of the pharaoh Tutankhamen and the men most frequently associated with the so-called Pharaoh’s Curse.

Fortunately, in the 2020s there’s a better, more affordable, and more accurate way than these distinctly analog and haphazard methods for locating underground objects, and Safe2Core has it!

Known as ground-penetrating radar (GPR) and sometimes referred to as ground probing radar or “georadar,” this technology has been used in data acquisition and location mapping for sciences ranging from geology and environmental geophysics to forensics and even search and

rescue operations after avalanches, building collapses, and other natural and manmade disasters.

Ground Penetrating Radar 101

The basic idea behind GPR technology is very simple: probes are inserted into the surface to be analyzed, creating electrical radar pulses created within the zone the probes mark off which in turn produce subsurface reflections from objects embedded within the native material. By moving the probes around within the “box” of the search zone, a complete image and record of the location of anything below the surface as far down as the radar frequencies used can reach is created.

GPR antennae within the control unit measure the difference between areas of high and low conductivity within this zone by reading the two-way travel times of the reflected signal, similar to the way a radar wave picks up solid objects in the air or on the water. More sophisticated modern multi-channel GPR units will “jump” across GPR frequencies to achieve the best balance between depth of penetration and accuracy in the readings, using advanced radio frequency signal processing to give the most complete possible picture of what’s buried within the testing zone, creating an image known as a GPR cross-section. For instance, if you wanted to do a radar survey and existing pipe inspection in a given area, a buried old-fashioned iron pipe or copper underground storage tank would typically show up in the GPR cross-section readily because the highly conductive metal is surrounded by low conductivity soils.

Ground-penetrating radar GPR wave technology is often employed in situations where there is very little margin for error and getting the precise information and accurate locations quickly could literally be a matter of life and death.

Of course, at Safe2Core, we hope our GPR systems will never be needed for stakes quite that high when using ground-penetrating radar for construction sites, but if they are, Safe2Core is proud to say we have the right equipment and GPR training for the job!

Some common GPR applications for construction sites include:

- 3D imaging

- Bridge deck asphalt and concrete inspection in situ

- Data collection

- Concrete scanning

- Nondestructive testing

- Concrete structural examination

- Public and private utility locating

- Subsurface structure location

- Subsurface utility identification, such as sewer lines

- Surveying subsurface objects and unknown/anomalous targets

- Underground utility mapping

- Seismic reflection evaluation

- And more!

To learn more about how Safe2Core’s ground-penetrating radar systems can help you get faster results with less expense and better coverage for your construction project, click here to contact us for your job. Also, be sure to check out our Frequently Asked Questions for more information about ground penetrating radar on construction sites and answers to questions about GPR from all over the country!

Frequently Asked Questions about Ground Penetrating Radar on Construction Sites

Question: How does ground penetrating radar work? –Ravi, Menlo Park, CA

Answer: At its most basic, GPR works on essentially the same principle as sonar or radar wave technology. The control unit sends pulses of electromagnetic waves into the material to be tested and a receive antenna measures the speed and rate of return. The unit’s radar antenna then converts the radar signal into an image, allowing the unit and its operator to detect the dimensions and shape, also known as the footprint, of many obstructions or voids in the material and produces an image of what lies below.

The longer, more complex answer: Modern GPR scan technology works on the principle of dielectric permittivity and interferometric signal analysis.

In layperson’s terms, the dielectric constant is the degree of electrical conductance, or lack thereof, in a given material. Every material, from human flesh and bone to the hardest metals and rocks on the planet, has an electromagnetic profile based on its conductivity and will reflect or absorb an electromagnetic scan in some way. Limestone will have a different electromagnetic energy signature than clay soil, and rare earth elements will typically show up differently than more commonplace metals. For a basic example of this, consider an MRI, which looks for variances in density between human tissues to identify fractures, soft tissue injuries, and even some forms of cancerous growth. In much the same way, GPR uses electromagnetic emissions pulsed into the ground to look for attenuation, or interference with and changes in the returning radar wave signal caused by absorptive and reflective differences between the properties of the materials within the area of the scan.

The technician sets probes into the ground which sets up an electromagnetic induction field, a process known as borehole GPR. By measuring the difference in electric properties between areas of higher or lower density and how the materials attenuate and create a variance in electromagnetic energy return between materials across a broad frequency range, the locating equipment translates the collected GPR signal into a comprehensive image which allows technicians and engineers trained in interpreting GPR data to locate variances in the electromagnetic properties of the material and create maps of the varying material properties for precise subsurface imaging.

Question: What are the applications of GPR? –Cedric, Los Angeles, CA

Answer: There are very few limits to the potential application of ground-penetrating radar, from obtaining geophysical survey data to solving crimes. It is used frequently in archaeology and forensic science for identifying and planning unearthing operations for subsurface structures, buried objects, and historical treasures or locating mass grave sites and unexploded landmines in war zones. It is used in geology and mining for geophysical data acquisition like locating natural resources and contaminant plume sources, as well as in situ soil testing for detecting areas of ice and water erosion or pockets of dry sand and gravel versus silty clay versus limestone. It is even used in search and rescue to locate survivors or victims of catastrophes from tsunamis to bridge collapses.

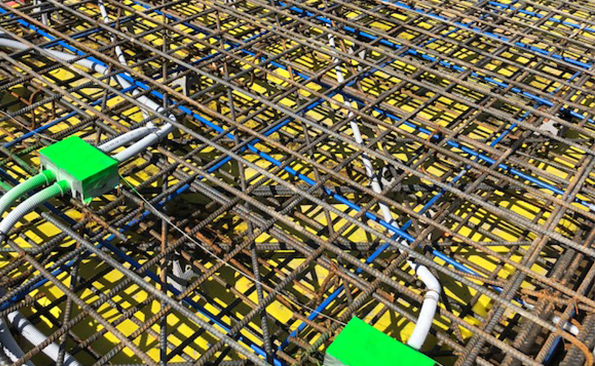

In construction, GPR is often used in reinforced concrete scanning and site surveying to help workers differentiate, locate and mark structural members and utilities such as rebar and water main or electrical lines within a slab or the soil.

Case studies of mobile GPR surveys have consistently demonstrated that GPR works with unparalleled efficiency and efficacy at finding hidden hazards, obstructions, and anomalies that warrant further investigation without the need for destructive testing or the risk of “blind” exploratory excavation.

Dual-borehole GPR locating equipment can be used to identify the precise GPS coordinates of pilings, footings, and other structures on both lateral and vertical trajectories. Multi-channel GPR, which uses multiple antennas at high and low frequencies, gives the most complete picture possible of a flat area with superior resolution and minimal interference.

By varying the antenna frequency range from high frequency to low frequencies and their inverse low to high definition, the depth ranging and depth penetration properties are enhanced, as is the overall picture. Basically, if it has mass and/or takes up space, and assuming it’s not made of PVC or a material with similar dielectric properties, modern GPR systems can detect it—saving companies time, money and risk!

Question: Why are GPR surveys such popular geophysical methods these days? –Jack, Clovis, NM

Answer: Ground penetrating radar GPR technology has proven to be an extremely reliable method of detecting subsurface aberrations that indicate the presence of disturbed soil and rock, as well as objects buried within them. One of the leading proponents of GPR applications of geophysics is Dr. Lawrence Conyers of the University of Denver. Dr. Conyers and his team have used GPR and related geophysical methods to identify indigenous burial sites from the Dominican Republic to Australia, as well as other points of archeological relevance. In many ways, Dr. Conyers wrote the book on what is possible with GPR and how to identify changes in subsurface conditions that can indicate the presence of subsurface objects from hidden structures to unmarked gravesites. His intensive use of GPR surveys in his work, and the vast amount of data collection his teams have conducted regarding the limitations of GPR, has prompted changes and refinements in GPR equipment and how GPR data is interpreted, allowing for greater accuracy and a wider potential range of ways in which GPR application in the field can be utilized.

Question: How fast can a ground-penetrating radar survey be conducted? –Liam, San Francisco, CA

Answer: One of the great things about using scanning and borehole GPR methods to conduct site surveys on bridge decks other concrete structural features is that it’s generally very fast and cost-effective, especially when compared to exploratory excavation or other geophysical techniques for subsurface investigation. When ground penetrating radar systems send an energy pulse composed of electromagnetic waves below the ground surface, the two-way travel times for the reflected radar signal are measured in nanoseconds. Think of this as a camera that captures a snapshot of subsurface features at a specific place at very high velocities. High-frequency GPR antennae offer a more defined picture but have a lower depth of penetration, while lower frequency antennas deliver greater penetrative power but less resolution. This means the scan may and likely will have to be repeated several times in a given area at different power levels and amplitude settings, but remember each scan happens at speeds about 1/1000th of the time it takes you to blink your eye! By varying the power of the reflected signal to the receiving antennas, the GPR records each scan individually as what is known as a “time slice.” Once the grid scan is completed and the data processed, the GPR measurements taken in these slices are “stacked” together and the locations of all the detected anomalies and voids are plotted to produce subsurface maps with three-dimensional imaging, giving a picture of what lies within the scanned area. The key limitation on how long you can expect a GPR survey to take on a given piece of property is the size and whether we’re performing known underground utility locating and pipe inspection or if we’re performing exploratory scanning. Likewise, scanning to locate rebar in a two-thousand-square-foot concrete pad six inches thick will take a lot less time than scanning for reinforcing steel in a ten-thousand-square-foot, one-meter-thick foundation footing. Any way you cut it, if you need to know what’s below the surface fast, you can always bet on GPR to show the presence of possible obstructions quickly and accurately.

Question: What are some of the limitations of GPR? –Alyssa, Miami Beach, FL

Answer: GPR is a handy tool and a very reliable one. However, like any other tool, there are some things it works better for than others. For example, one thing many users, like Dr. Lawrence Conyers, have remarked on is the fact that GPR cannot usually pick up human remains. Grave location is often more of a matter of detecting changing soil conditions and ground disturbances, such as an area abruptly and unexpectedly moving from dry sand to wet clay, or solid objects that are interred with the dead, because the dielectric constant of human flesh is quite similar to that of soil. This means the electrical conductance and dielectric properties of human cadavers will essentially allow the GPR waves to pass right through. Contrast this with rebar or other high conductivity materials, which tend not to attenuate the signal and create a clearer, sharper contrast.

Another limitation is the fact that, although sending GPR energy into the ground can tell you “something” is down there, it can’t necessarily identify what specifically it is, particularly if the dielectric permittivity of the material in question is similar to the surrounding matrix. This is especially true when dealing with pockets of rare earth materials or groundwater in bedrock, as opposed to leaking freshwater pipelines in clay or sand, because of the ways in which these materials can cause attenuation of the radar signal. Interpreting GPR signal processing for an accurate assessment of subsurface conditions is as much of an art as a science.

Fortunately, georadar systems such as ground probing radar have gotten more sophisticated and far easier to use and read over the years. Advances in digital control give the operator superior control over every aspect of the scan, while sophisticated remote sensing technology and seismic reflection evaluation have made it easier for the boundary between materials to be interpreted. This means that despite the limitations scanning by GPR into ground material can have, it is still the best non-destructive testing method for obtaining a detailed investigation of a given material or area!

Question: Does GPR work like a fish finder? –Wilford, Austin, TX

Answer: While GPR and fish finders work on similar principles, they’re not exactly the same. GPR emits electromagnetic energy pulses for detection and mapping of anomalies, embedded materials, and buried structures in concrete, asphalt, or soils based on their electrical profiles. This type of electromagnetic pulse reacts to the conductive properties of various subsurface materials within the penetration depth range of the GPR transmitter to develop data about ground changes which indicate the presence or absence of subsurface features. Fishfinders typically use the echoes from high-frequency sound waves, or sonar, to pick up the presence and approximate size of fish in the area. While they both display information in a similar way through the user interface by using hyperbolas to indicate the potential presence of targets, their internal workings are vastly different. Additionally, GPR typically cannot be used in water, while the type of transmitting antenna used in fish finders is almost exclusively designed to be used underwater or in waves where the transducer can be fully immersed. Finally, and perhaps most importantly, a fish finder is relatively underpowered compared to a GPR unit, which has to be able to emit far more electromagnetic radiation in order to achieve maximum range and detection depth through granite, limestone, gravel, concrete, and other materials.

Question: Are there advantages to a digital GPR system over analog systems? –Beverly, Anaheim, CA

Answer: In most cases, absolutely there are. Among other advantages of ground penetrating radar, a digital GPR system generally delivers a more comprehensive picture, in a more compact unit, with less downtime and greater accuracy. Digital GPR locating system units also tend to offer a greater penetration depth, heightened sensitivity, and a wider array of available frequencies they can deploy, which makes digital GPR units a favored tool that detects changes in seismic reflection and electrical properties that may be of interest to practitioners in fields ranging from archaeology to geology to modern environmental geophysics and forensic science. Naturally, digital GPR systems are also preferred in construction for utility mapping, detecting rebar and posttension cables in concrete, locating failed or failing areas in roads, and identifying areas of unexpected high water content that may indicate damaged utility lines, just to name a few possible uses. There are some circumstances where an analog system may be a better choice, but this is very circumstantial and needs to be evaluated on a case-by-case basis. Please contact Safe2Core so we can help you decide whether digital or analog GPR is going to be most helpful for your specific site and situation!

Question: Can ground-penetrating radar detect through concrete? –Buddy, Tucson, AZ

Answer: Honestly, it depends. High-frequency GPR scans can deliver more accuracy in planning drilling, coring, and cutting operations, but they have a lower depth penetration. Conversely, low-radio frequency GPR has greater depth penetration but lower accuracy. Slab depth and thickness, the mix design of the concrete, the properties of the material underneath, existing utilities, natural and manmade electromagnetic fields in the area, varying areas of seismic reflection, the presence or absence of utilities in the scan area, rapidly changing material properties including electrical conductivity, and other factors can all impact the accuracy and penetration of the GPR systems and the resolution of the overall readings. However, a multi-channel GPR can overcome these limitations and give a comprehensive picture of what’s embedded within and below the slab.

Question: How are GPR methods better for concrete inspection than other non-destructive testing methodologies like X-ray? –Enrique, Littlefield, AZ

Answer: For starters, unlike other geophysical methods, ground-penetrating radar methods have far more customer testimonial and field study evidence, as well as more private companies and government agencies such as the US Department of Defense’s Army Corps of Engineers relying on it, to demonstrate they work better and give clearer results, with fewer limitations and less ambiguity, than X-ray.

X-ray examination is limited mainly to walls because there have to be two plates, one on each side of and in direct contact with the surface, to achieve the optimum results. In cases where two plates can’t be placed, everything beneath the scanner becomes a scientific wild guessing game.

More to the point, X-ray cannot deliver the same clarity or precision as GPR as a general rule, even with the latest digital X-ray devices.

Even worse, when using X-ray equipment, safety considerations and the radioactive emissions from the unit require that all operations within a prescribed range of the unit have to be shut down during the time the unit is running. Otherwise, you risk getting images that are mangled or wholly unusable and impossible to interpret, not to mention the associated safety issues.

GPR also has the advantage of superior data processing capabilities in most cases, meaning it delivers a clearer and more accurate picture of unmarked underground utilities, structures, and reinforcing members faster.

It takes less time to do the scan and to interpret the results, meaning less interference and downtime for your crew. Even better, you can use GPR equipment without having to shut down significant areas of the site during the test in order to get a clear picture. This gives you the information you need to help you decide how, when, and where the ideal place is to make cuts, core samples, and perform other operations without risk of damage to subsurface utilities.

Question: What is subsurface imaging? –Millicent, Phoenix, AZ

Answer: Subsurface imaging is the science and art of scanning the material below a surface, such as soil, concrete, or asphalt, and detecting the obstructions, imperfections, and voids within the material which might not be visible to the naked eye. It is predicated on the theory that everything from bedrock to plumbing pipes has some sort of electrical signature, and that given the right kind of electromagnetic pulse feeding back to properly tuned antennas, it is possible to identify changes in material that can show where and how deeply it is located, and to some extent work out what it is from known available data and its overall shape and dimensions. Until recently, this was usually accomplished by using X-rays and trying to match them up with the site drawings and as-built

documents, assuming they were reasonably accurate. With the advent of ground-penetrating radar and GPS, along with the accuracy of as-built site drawings, the sensitivity and accuracy of subsurface imaging have increased exponentially. As of this writing, as long as the less conductive conduits and pipes under the surface are marked with conductive tape, which they have been as standard practice since around 2003, the images produced by ground-penetrating radar scanning can produce a precise and accurate three-dimensional mapping of the area below the surface.

Question: Does GPR work to detect underground utilities? –Bill, Austin, TX

Answer: For most metallic and solid utilities, such as electrical lines and septic tanks or other subsurface structures, yes. Likewise, rebar, post-tension cable, and other structural reinforcement within a given slab or section of concrete will show up with no issues in most circumstances, barring unusual electromagnetic properties or other anomalies in a specific area. However, some types of utility lines, such as old-fashioned clay water and sewer pipes or those made of PVC and similar materials, may and often don’t show up on GPR scans because their electromagnetic profile mimics or blends in with that of the surrounding material.

As this is a known issue that affects nearly every known type of nondestructive subsurface investigation, a simplified solution needed to be found to avoid unnecessary damage to these utilities.

Since 2003, most regulatory agencies and building departments across the country require that pipes and conduits made of PVC or materials with similar electroconductive properties which may not show up on a scan on their own must be specially marked. Generally, this is accomplished in one of two ways.

Contractors often use special color-coded polarized conductive safety tape, placed along the entire length of the line from the utility meter to the limit of the job site, to increase the relative reflection profile of the line on sub-surface scans. This media is typically placed in the trench at a distance of about a foot above or to the side of the line. When future excavation occurs, the tape will ideally be seen by the person doing the excavation before they hit the actual utility and know to proceed with caution as they dig down to their depth targets. Because the tape is color-coded, the idea is that the operator will be immediately able to determine if they’re near water, gas, or electrical line at a glance.

In cases where the tape is not required or deemed impractical, another solution in common use is a guidewire that traces the length, depth, and direction of the pipe. As long as we can match up the relative depth of the utility with its meter and placement on the drawings and other site records, Safe2Core can give your crew precise target locations with a very small margin of error and help assure your excavation or placement project is exactly located to avoid utilities.

Question: What is the penetration depth for ground-penetrating radar? –George, New Braunfels, TX

Answer: The penetration depth for GPR scans is dependent on the frequency range and power of the scan, the density of any intervening material such as pavement or stone slabs, the concrete or asphalt mix design, and so on. It can vary from 100 feet (30 meters) to less than six inches. High-frequency scans show a greater resolution, but can’t penetrate more than a few inches. At lower frequencies, you get less resolution but much deeper overall penetration. Varying the use of high-frequency antennas in the high megahertz (MHz) to gigahertz (GHz) range and lower radio frequency radar antennae can give a more comprehensive picture deeper into the material. However, the material beneath the concrete or asphalt makes a difference as well and can slow down the scanning process. Native material composed mainly of dry sand and gravel will give a clearer return at a higher velocity and lower depth than saturated silty clay, for example. Using a combination GPR unit at high and low frequencies can help overcome this to a degree, with a little noticeable impact on scanning speeds. For the best results, we’ll have to see the site, the thickness of the slab on grade, the characteristics, and the material underneath as well as the as-builts and drawings for your site to determine the best approach and ensure we can deliver the most accurate picture possible and the maximum safety for your crew.

Question: Is GPR scanning safe? –Derek, Taos, NM

Answer: GPR scanners use radio waves, which move at the speed of light. Unlike X-rays or other types of radiation such as the kind nuclear density gauges rely on to give soil and asphalt compaction readings, radio waves are simply electromagnetic energy that permeates the entire universe. You’re surrounded by these radiated waves all day, every day, when you use devices like Bluetooth, your car radio, your cell phone, or just stand still out in the middle of nowhere, and they’re perfectly harmless.

While some people view any kind of radiation as instantly unhealthy, the truth is that the radioactive emissions from the screen you’re reading this on have been proven to be far more hazardous to your health than a GPR scanner, even if you were standing on it all day.

The only risk GPR scanning typically involves is to the technician if they handle or carry the scanner carelessly and strain their back or drop the unit on their foot!

Question: Are GPR emissions going to put my work crew at risk of health problems? –Bobby, Las Vegas, NM

Answer: Absolutely not! GPR requires no special or enhanced safety precautions either for the technician or surrounding personnel, unlike a nuclear density gauge which requires specialists to wear a radiation badge and mandates generous space between non-users and the unit while it’s operating. Because of this, GPR is one of the safest and most comprehensive ways of performing nondestructive testing and mapping unmarked lines and obstructions in the soil or concrete quickly and effectively!

Question: Will the GPR signal interferes with other instruments operating in the area? –Deanna, San Mateo, CA

Answer: In general, no. The modern technology utility locating equipment uses is sophisticated enough, and GPR scanners are self-contained enough, to prevent cross-interference. Any interference other receivers, such as GPS location and site radios, can pick up should be minimal to nonexistent. As long as the equipment is not parked directly on top of the scanner, or vice versa, there shouldn’t be any interference or impact on how the devices work on either side. However, a direct examination of the equipment will tell us if there are any special considerations we need to take into account to ensure there are no issues either with your communications and location equipment or our scanners.

Safe2Core is your source for fast, accurate utility and subsurface structure location and identification. Whether you need utility marking on a private site before breaking ground or nondestructive concrete inspection after slab placement, we’re here to help with the latest ground-penetrating radar technology for quick results and maximum crew safety.