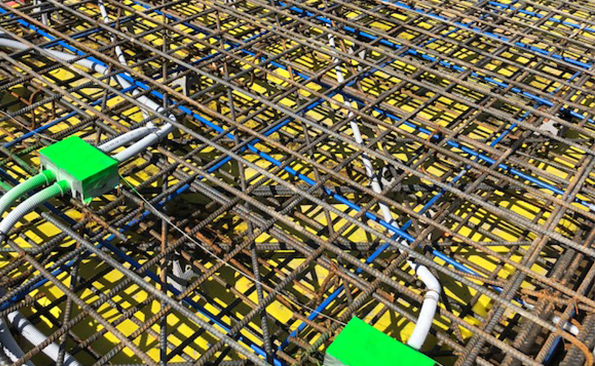

Our 3-person crew arrived at a mixed-use commercial and residential high-rise at 91 Red River Street in Austin with one week to scan both an 18” steel rebar-reinforced floor and an 8” slab reinforced with post-tension cables. Based on the surface area and overall dimensions of the slab, they would also have to cut 55 cores from the 18” slab and a further 12 core holes on the 8” slab for archival, testing, and approval by the project’s structural engineer of record, or EOR.

Two key factors complicated the job. First, there was so much rebar within the 18” slab that the structural steel served to occlude the electrical conduits the as-built plans showed in the matrix, creating an obvious and potentially lethal electric shock hazard. Second, the presence of so much rebar would slow the coring time considerably, as there was no way to avoid cutting through the rebar itself at the selected core locations once the crew determined where the conduits and other utilities were located.

Reinforcing steel is the backbone of most sturdy construction projects, but too much of anything is not necessarily a good thing. If there’s too much reinforcing steel present, or the rebar mat is too dense, the rebar will reflect and scatter the GPR unit’s return signal, making it virtually impossible to see past it and detect other things in the matrix without resorting to some esoteric measures. The ability of metals like steel to reflect and confuse radar signals is the basis for the use of so-called “chaff,” confetti-like metallic strips that help prevent surface-to-air missiles from locking onto an aircraft.

We used electromagnetic induction to solve the first issue and connected it to the main electrical panel. This allowed us to trace the conduits through the slab. From there, we were able to run our GPR scan, marking out the induced conduit as we went to identify safe points at which to harvest the required cores.

The second issue was less technically challenging but more time-consuming. We try to avoid coring in areas where we know there’s rebar, but given the characteristics of the mat around which the concrete was poured, there was simply no way to core without hitting at least some of the rebar. Since our crew had the necessary coring equipment to penetrate the slab and the mat, this wasn’t an obstacle, but coring through the rebar at multiple levels within the matrix added considerable time to the process. The presence of so much rebar also slowed the approval of the slab by the structural EOR.

In the end, we’re happy to report that the structural EOR approved the slab based on the cores and GPR data Safe2core Inc. provided. The coring project was completed safely and without damage to the conduits or other utilities. When our crew left the job site at the end of the week, they left a happy client with a project on schedule.

Safe2core Inc. is proud to serve our customers in Texas, Arizona, California, and South Florida with quality nondestructive construction site scanning as well as cutting, drilling, coring, and sawing operations that get the job done quickly correctly, and most important of all safely. Our menu of services includes:

- Concrete grinding and grooving

- Concrete removal

- Concrete sawing

- Concrete scanning

- Facilitating CCTV pipe inspections and vacuum excavation operations

- Flat sawing

- GPR detection of plumbing, electrical, gas, and water lines

- Locating underground utilities

- Safety grooving

- Sanitary and storm sewer inspection and location

- Slab sawing

- Subsurface utility engineering and planning

- Wall sawing

- Wire sawing

- And more!

Also, we’re pleased to welcome our new Texas customers with a special offer: 4 free hours of GPR scanning when you use the coupon code “45Back” for your first project with Safe2core Inc. We’re confident that once you’ve seen how fast, efficient, effective, and safe we can make your private utility and construction cutting work, you’ll keep calling us for all your projects. That’s the Safe2core Inc. difference, and we’re excited to demonstrate it to you. Simply click here to contact Safe2core Inc. through our website or email us at contactus@safe2core.com with the project specs and the types of service you need. Make your construction project run safer and smoother with Safe2core Inc!