Sometimes when drilling and sawing, it can be difficult to achieve a cavity of the correct size or shape using conventional methods such as floor sawing, wire sawing, or ordinary diamond drilling. Coring and drilling operations are both limited in the size and depth of the holes they can achieve by the size of the core and drill bits in play. For large construction industry jobs where larger hole sizes or unusual shapes are required, such as in aiding soft strip and robotic demolition efforts, diamond stitch core drilling may be the correct option in situations when other diamond concrete cutting, sawing, and drilling methods aren’t sufficient to achieve the required hole size or shape for the job for some reason. Safe2Core has the experience and skill to perform concrete stitch drilling safely and effectively!

What is diamond stitch core drilling?

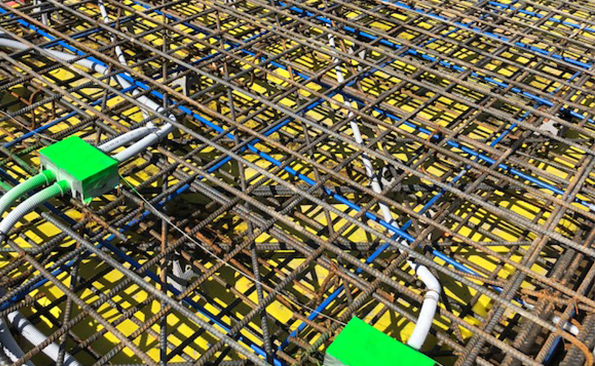

Diamond stitch core drilling, also known variously as stitch coring, stitch drilling, or simply “stitching,” is a drilling method that uses a diamond-impregnated bit on a concrete coring rig to cut a chain of multiple overlapping core holes which, in turn, create a single large hole or cavity. One of the major benefits of this method of concrete drilling is that the chain of holes created this way can be controlled, drilled, and shaped to form a bigger hole of virtually unlimited size and shape at nearly any depth your project might need, allowing you to cut larger and more precisely shaped holes through concrete and other materials faster while working to overcome the limitations imposed by other drilling and sawing methods. The process requires no special preparation other than preliminary concrete scanning to mark out obstructions in a wall or floor before cutting, and no special equipment beyond the core drill plinths and bits necessary to create the holes, helping to keep project and site costs minimal while creating the required access for everything from fire protection system runs to large gas pipes and conduits.

Why use stitch drill coring over other types of drilling?

Stitching is a highly versatile process that is used when diamond cutting through other means, such as track sawing, won’t work. Possible uses include needing to make a wide hole within a tight space so conduit or pipe course placement work can continue, to keep down dust and debris from a cutting project in restaurant and hospital building jobs, or other situations where health and safety considerations demand it, or simply creating a hole that’s over the size other diamond drilling and sawing methods can deliver.

A project manager may choose stitching to keep the time and financial cost of cutting in a specific situation or make this call in a case where the project design requires a hole of a specific size to be created, but the onsite conditions prohibit other methodologies.

Due to the flexibility and efficiency of stitching and how fast and easy it is to do, it has become the highly preferred alternative over other professional diamond cutting methods, such as drills that may take more time to deliver less effective results if it’s even possible for them to do so at all.

However, just having the most effective method for your diamond drill stitch cutting needs doesn’t mean much without highly trained and skilled specialist operatives to execute the work and deliver excellent results—which is where Safe2Core comes in!

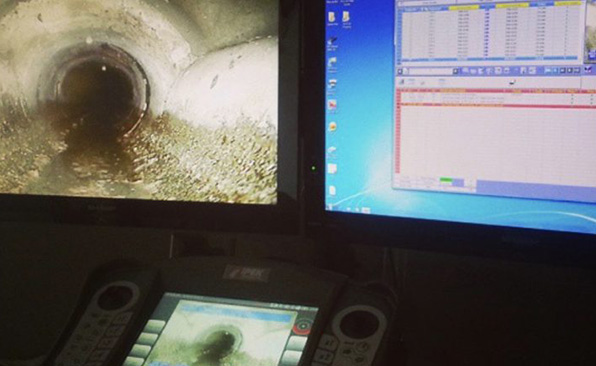

For years, Safe2Core has been the name recognized nationwide for the best and latest in safe, effective, efficient utility location, concrete scanning, and more. We use state-of-the-art technology, from ground penetrating radar (GPR) for concrete scanning and utility location to a complete suite of services diamond-based tools permit so we can drill, cut, saw, and core through hard material faster, safer, and more economically. Our specialists are always working very hard to make your jobsite operations as efficient as they can possibly be. To request a quote for services on your job site, we invite you to please contact us through our website today by clicking here to send us a message, or you can give a call to the Safe2Core office nearest you. And to find out more about how and why stitch drilling diamond coring might be the first choice your site needs to keep working smoothly, keep reading for our answers to frequently asked questions about diamond stitch drilling from construction professionals just like you!

Frequently Asked Questions About Diamond Stitch Drilling

Safe2Core is your source for concrete scanning and cutting services that construction industry professionals trust, plus real talk and straight answers about all your utility locating and scanning, cutting, and coring needs!

Question: How does diamond stitch drilling differ from other concrete cutting methods? –Chase, Phoenix, AZ

Answer: Whether you’re sawing floor or wall holes, there’s only so much even a very strong saw or drill can do. While these tools usually work quite well in terms of straightforward hole creation, they aren’t always the best choice for needing to make very large or unusually shaped holes. Blasting out holes of this type using conventional methods can lead to chasing down unnecessary problems, such as pipe bursting from punctures during the process, so you can address them.

On the other hand, stitching is usually paired with concrete scanning services, which means you’ll always know what’s below the surface of the concrete without having to search through old records just to get “close” to what might be there, such as post-tensioning cables and other hazards.

The fact is that coring a number of holes in a specified pattern is a particularly fast and effective way of making large or custom-created holes that then means you can keep your workers working faster and with less worry about whether other techniques will get the job done, so stitch core drilling is to thank for the last word in efficient cutting! That’s why many previous methods of cutting, like wire sawing, track sawing, and conventional drilling, are now considered less desirable methods when this type of operation is called for today.

Question: Can diamond stitch core drilling be used on a mouse pad? –Elmer, El Paso, TX

Answer: Yes! Stitching can be used anywhere there’s concrete, such as on a road bridge, a mouse pad, or through a wall in an industrial or tech complex. No matter what size or shape of hole you need or what you need to pass through it, stitching is a very efficient and elegant method of getting the job done quickly and precisely without it getting out of hand. This is why diamond stitch drilling is the new standard in large-bore and odd-shaped hole cutting and why we expect it will be for years to come!

To find out more about how Safe2Core can make your diamond stitch drilling project safer, more efficient, and more economical for your site’s bottom line, click here to contact us today!